CHARACTERISTICS OF OPERATING ROOM DOORS

1. Operating room door has good sealing performance, flexible switches, beautiful appearance, convenient installation, durability, and beautiful

appearance, meeting the requirements of national cleanengineering construction technical specifications.

2.All aluminum profiles are treated with oxidation or electrophoresis.

3. Mostoperatingroom doors use automatic doors, such as operating room foot sensing doors or operating room electric doors.

The electric airtight door of the operating room is designed specifically for places with cleanliness requirements, mainly used in

hospital operating departments, purification wards, general wards,laboratories, clean workshops, etc.

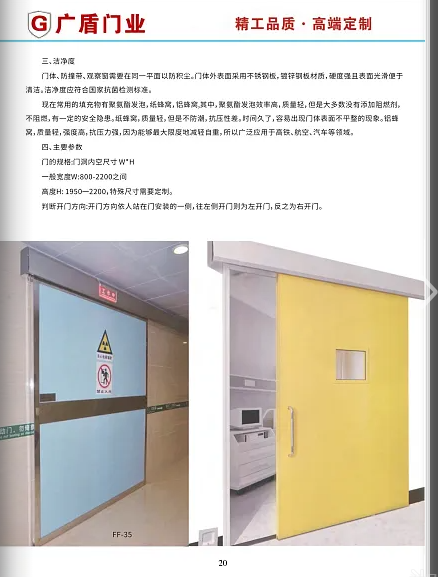

Automatic Sliding Doors for Operating Rooms

Operating room doors typically require high levels of airtightness and cleanliness. The door leaf is designed with an internal frame structure filled with flame-retardant honeycomb paper, reinforced with a high-strength aluminum alloy frame, and formed through an advanced hydraulic press system. Specialized equipment and techniques are employed to ensure the door’s surface remains flat and even. The surface color can be customized with a powder coating as per user requirements. Additionally, the doorframe is lined with thickened sealing strips to meet the hygienic standards required in hospitals.

Operating Room Door Related Features

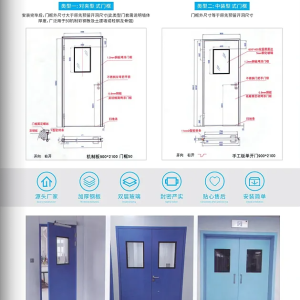

**Door Body**: The total door thickness is approximately 4 cm, with single-sided colored steel panels of 0.8 mm thickness. The door can be opened either once or twice, depending on the actual site needs. The color and finish can also be customized according to the customer’s specifications, and the surface can be painted.

**Sealing Strips**: Sealing strips are applied around the door body, providing a tight seal where the door meets the wall, enhancing its airtightness.

**Viewing Window**: Also known as the observation window, it is made from double-layered SLR hollow glass, allowing visibility from one side. The size of the window can be customized based on the door dimensions.

**Anti-Collision Belt**: A wide anti-collision belt runs across the middle of the door, typically made from stainless steel. This feature helps prevent damage from impacts while adding to the door’s aesthetic design.

**Sliding Track**: The sliding track for the operating room door is part of the system that allows the door to slide open or close and secures the door in place.

Operating Room Door Related Functions

1. Functionality

The operating room doors are controlled by a microcomputer, allowing for humanized settings such as adjusting door opening and closing speed, the duration the door remains open, door force, and the starting position for slow speed. The system has memory capabilities and features anti-pinch protection. When resistance is detected during the opening or closing process, the door will automatically respond by reopening or closing. Multiple opening methods are available, including manual control, infrared sensor, microwave sensor, and foot control. The door is equipped with a built-in handle to ensure manual opening in the event of a power failure, making it suitable as an evacuation door. The system can integrate with various access control systems, fire systems, and security systems to ensure proper management of door operations.

2. Airtightness

The sliding track is made from high-strength aluminum alloy, precisely processed using CNC technology for smooth operation and low noise. Adjustable suspension components allow fine-tuning of the door’s position when necessary. Medical-grade silicone sealing strips around the door make contact with the rubber strips on the aluminum alloy frame, ensuring the airtightness of the door meets national standards. In high-grade cleanrooms, such as those with Class 100 purification requirements, the door must be equipped with an automatic sinking track for enhanced airtightness.

Here’s an English translation of the additional sections, focusing on cleanliness and key parameters of the operating room door:

—

#### 3. **Cleanliness**

The door body, anti-collision belt, and observation window must be flush with each other to prevent dust accumulation. The outer surface of the door is made from stainless steel or galvanized steel, offering high hardness and a smooth surface that is easy to clean. The cleanliness of the door should comply with national antibacterial testing standards.

Common filling materials include polyurethane foam, paper honeycomb, and aluminum honeycomb:

– **Polyurethane foam** is efficient and lightweight but often lacks flame retardants, making it non-fire-resistant and posing safety risks.

– **Paper honeycomb** is lightweight but not moisture-resistant and has poor compressive strength, which may cause surface irregularities over time.

– **Aluminum honeycomb** is lightweight, strong, and has high compressive strength. Due to its ability to reduce overall weight, it is widely used in industries like high-speed rail, aviation, and automotive.

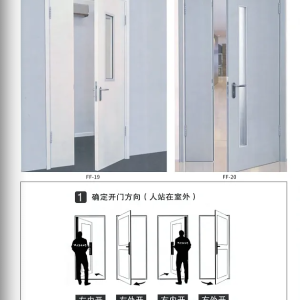

4. Key Specifications **Door Dimensions**: Opening dimensions (W * H)

– Standard width (W): Between 800 mm and 2200 mm

– Height (H): Between 1950 mm and 2200 mm (custom sizes available)

**Determining the Door Opening Direction**:

The door’s opening direction is determined by standing on the side where the door is installed. If the door opens to the left, it is considered a left-opening door, and if it opens to the right, it is a right-opening door.

drover sointeru –

Have you ever thought about adding a little bit more than just your articles? I mean, what you say is fundamental and all. However think about if you added some great visuals or video clips to give your posts more, “pop”! Your content is excellent but with pics and videos, this site could certainly be one of the best in its field. Wonderful blog!

yunngd2024 –

Thank you for the reminder. I will add more engaging images and videos, as well as interesting content.