General Technical Requirements for Medical Door in Building Construction

This document outlines the general technical requirements for medical door used within building constructions, particularly in hospital environments. It covers terminology, classification, specifications, materials, construction standards, testing methods, inspection rules, and packaging guidelines.

1. Scope

This document specifies the terminology, classification, specifications and markings, requirements, testing methods, inspection rules, packaging, labeling, transportation, and storage for medical doors intended for indoor use in hospital buildings.

2. Medical Door Normative References

The following documents are essential to this standard through normative references. For documents with specified dates, only the version corresponding to that date applies; for those without, the latest version (including all amendments) applies:

- GB/T 191: Packaging and Storage Symbols

- GB/T 708: Dimensions, Shapes, Weights, and Tolerances of Cold-Rolled Steel Plates and Strips

- GB/T 1470: Lead and Lead-Antimony Alloy Plates

- GB/T 1732: Test Method for Paint Film Impact Resistance

- GB/T 2423.1: Environmental Testing of Electric and Electronic Products – Part 2: Test A – Low Temperature

- GB/T 2423.2: Environmental Testing of Electric and Electronic Products – Part 2: Test A – High Temperature

- GB/T 2423.3: Environmental Testing of Electric and Electronic Products – Part 2: Test Cab – Constant Humidity

- GB/T 2423.17: Environmental Testing of Electric and Electronic Products – Part 2: Test Ka – Salt Spray

- GB/T 2518: Continuous Hot-Dip Galvanized and Zinc-Alloy Coated Steel Plates and Strips

- GB/T 3280: Cold-Rolled Stainless Steel Plates and Strips

- GB/T 3797: Electrical Control Equipment

- GB 4343.1-2018: Electromagnetic Compatibility Requirements for Household Appliances, Electric Tools, and Similar Devices – Part 1: Emission

- GB 4824-2019: Industrial, Scientific, and Medical Equipment – Limits and Measurement Methods for Radio Frequency Interference

- GB/T 5171.1: Small Electric Motors – Part 1: General Technical Conditions

- GB/T 5823: Terminology for Building Doors and Windows

- GB/T 5824: Series of Door and Window Opening Sizes

- GB/T 6388: Marking for Transportation Packaging

- GB/T 6739: Determination of Paint Film Hardness – Pencil Method

- GB/T 7106: Testing Methods for Air Permeability, Water Tightness, and Wind Pressure Resistance of Building External Doors and Windows

- GB/T 8478: Aluminum Alloy Doors and Windows

- GB/T 8485: Classification and Testing Methods for Airborne Sound Insulation of Building Doors and Windows

- GB/T 9286-1998: Paint and Varnish – Cross-Cut Test

- GB/T 9969: General Principles for the Use Instructions of Industrial Products

- GB/T 12190: Measurement Methods for Shielding Effectiveness of Electromagnetic Shielding Rooms

- GB/T 13306: Signs

- GB/T 14155: Soft Impact Tests for Whole Doors

- GB/T 14683: Silicone and Modified Silicone Building Sealants

- GB 15763.3: Safety Glass for Building – Part 3: Laminated Glass

- GB 15763.4: Safety Glass for Building – Part 4: Homogeneous Toughened Glass

- GB/T 16776: Silicone Structural Sealants for Building

- GB 18871: Basic Standards for Protection Against Ionizing Radiation and Safety of Radiation Sources

- GB/T 20909: Steel Doors and Windows

- GB 21556: General Technical Conditions for Lock Security

- GB/T 24343-2009: Insulation Resistance Test Specification for Industrial Electrical Equipment

- GB/T 24498: Sealing Gaskets for Building Doors and Windows, Curtain Walls

- GB/T 29049: Whole Door Vertical Load Test

- GB/T 29555: Testing Methods for Opening and Closing Force of Doors

- GB/T 30591: Coordination Requirements for Building Doors and Windows Opening Sizes

- GB/T 31433: General Technical Conditions for Building Curtain Walls and Windows

- GB/T 34616: General Technical Requirements for Pedestrian Automatic Doors

- GB/T 35379: Classification and General Technical Requirements for Wooden Doors

- GB/T 50719: Engineering Technical Specifications for Electromagnetic Shielding Rooms

- GBZ 120: Clinical Nuclear Medicine Radiation Health Protection Standards

- GBZ 126: Radiation Protection Requirements for Electronic Accelerator Radiation Therapy

- GBZ 130-2013: Radiation Protection Requirements for Medical X-Ray Diagnosis

- JC/T 635: Sealing Wool for Building Doors and Windows

- JG 305-2011: Safety Requirements for Pedestrian Automatic Doors

- JG/T 455: Toughened Glass for Building Doors and Windows Curtain Walls

- JGJ 113: Technical Regulations for the Application of Building Glass

- WS/T 512: Cleaning and Disinfection Management Specifications for Environmental Surfaces in Medical Institutions

- YY 0292.2: Protective Devices for Medical Diagnostic X-Ray Radiation – Part 2: Protective Glass Plates

3. Terminology and Definitions

The terms and definitions provided in GB/T 5823 and the following are applicable to this document:

3.1 Medical Door

A medical door that can isolate two environmental sides, achieving certain cleanliness, sound insulation, air tightness, or radiation protection requirements.

4. Classification, Specifications, and Marking

4.1 Classification in Medical Door

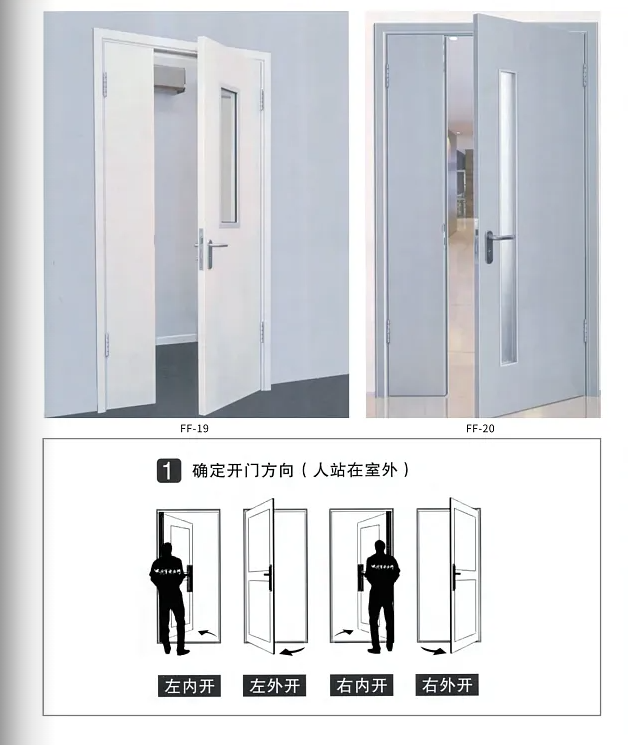

4.1.1 By Opening Method

The classification and codes for medical doors by opening method are as follows:

| Opening Method | Code |

|---|---|

| Swing Door | PK |

4.1.2 By Opening Power

The classification and codes for medical doors by opening power are as follows:

| Opening Power | Code |

|---|---|

| Automatic Door | ZD |

| Manual Door | SD |

4.1.3 By Application Category

The classification and codes for medical doors by application category are as follows:

| Structure Type | Code |

|---|---|

| Ordinary | P |

| Air Tight | Q |

| Radiation Proof | F |

| Magnetic Shielding | C |

Note: Combined functions can be represented by overlapping codes; for example, an air-tight radiation-proof medical door is coded as QF.

4.2 Specifications

The specifications of medical doors are indicated by the dimensions of the opening, which should comply with GB/T 5824 and GB/T 30591.

4.3 Marking

4.3.1 Marking Method

The marking method for medical doors consists of the medical door code (YY), opening method code, opening power code, application category code, specifications, and the standard number:

YY—GB/T ××××—202×

- Medical Door Specifications

- Application Category Code

- Opening Power Code

- Opening Method Code

4.3.2 Marking Examples

Example 1: Medical smooth automatic door, air-tight application, suitable for an opening width of 1400mm and height of 2100mm, marked as: YY-PH-ZD-Q-14002100 GB/T ××××—202×.

Example 2: Medical swing manual door, ordinary application, suitable for an opening width of 1400mm and height of 2100mm, marked as: YY-PK-SD-P-14002100 GB/T ××××—202×.

5. Structure, Materials, and Accessories

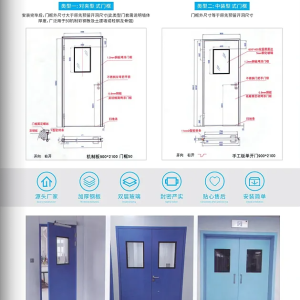

5.1 Medical Door Structure

The door structure must have sufficient rigidity and should meet the following requirements:

- The door leaf should have a handle positioned 900mm from the ground.

- Medical doors should be equipped with glass windows; patient room doors must have glass windows.

- Restroom doors should have louvered openings at the bottom.

5.2 Materials

5.2.1 Door Body Materials

The materials for the door body must possess sufficient strength and rigidity. Acceptable materials include steel, aluminum alloy, wood, glass panels, and others, complying with national standards.

5.2.2 Steel Door Specifications

When using cold-rolled steel plates, galvanized steel plates, or stainless steel plates, the nominal thickness of the door frame should not be less than 1.2mm, and the door leaf should not be less than 0.6mm. The allowable thickness deviations should conform to GB/T 708, GB/T 2518, and GB/T 3280.

5.2.3 Surface Coating Requirements

Steel doors should have surface coatings selected based on functional requirements, meeting the following criteria:

- Coatings should be firm and durable, with impact resistance according to GB/T 1732.

- Coatings should withstand common disinfectants, referencing WS/T 512.

- Adhesion strength should not be below level 2 of GB/T 9286-1998.

- Scratch hardness must meet GB/T 6739 standards.

- Neutral salt spray duration should not be below the standards of GB/T 2423.17.

- The affected area from coating loss at cut edges and intersections should be less than 15% of the cutting area.

- Surface scratches must comply with specified requirements.

Medical door

| Project | Requirement |

|---|---|

| Total scratch area | < Coating thickness |

| Each scratch area | < 3% of the total area |

| Adhesion test result | > Level 2 |

| Impact resistance | > 50cm |

5.3 Accessories

5.3.1 Door Frame

- The door frame should be made of durable materials with smooth surfaces and appropriate finishes, ensuring proper alignment and stability when installed.

- Frame dimensions must correspond with the specified opening sizes.

5.3.2 Hinges and Handles

- Hinges and handles should be resistant to corrosion and wear, easy to operate, and ergonomically designed.

5.3.3 Glass Panel

- Glass panels must comply with GB 15763.3 or GB 15763.4 for safety standards.

6. Testing Methods about Medical Door

6.1 Medical Door Performance Testing

Performance testing for medical doors shall include:

- Air permeability and water tightness tests according to GB/T 7106.

- Sound insulation tests according to GB/T 8485.

- Impact resistance tests for the door structure.

6.2 Inspection Rules

The inspection rules for medical doors should comply with the following:

- Inspection shall be conducted before shipment, ensuring products meet specified standards.

- Acceptable sampling methods will follow GB/T 2828.1.

7. Packaging, Labeling, and Storage

7.1 Packaging about Medical Door

Packaging of medical doors should:

- Protect against physical damage during transport.

- Include moisture-proof and anti-corrosive materials.

7.2 Labeling

Labeling should indicate:

- Product specifications, including size and material.

- Handling and storage instructions.

- Manufacturer and certification details.

7.3 Storage

Medical doors should be stored in a clean, dry environment to prevent contamination and degradation. Ensure that products are kept away from direct sunlight and extreme temperatures.

Conclusion

Medical doors play a crucial role in maintaining the safety and hygiene standards within healthcare facilities. This document serves as a comprehensive guide to ensure that medical doors meet the necessary requirements for performance, safety, and usability in various healthcare settings.

Reviews

There are no reviews yet.