Wooden Fire Door – Stylish and Reliable Fire Protection

Our Wooden Fire Door combines aesthetic appeal with essential fire safety. Designed for residential and commercial use, these doors offer both a sophisticated look and reliable fire resistance to protect your property and ensure safety.

Key Features:

- Fire Resistance: Built to withstand high temperatures, providing up to 60 minutes of fire protection (Class B).

- Elegant Design: Crafted from premium wood with customizable finishes to complement any interior.

- Durable Construction: Strong, solid core design for long-lasting performance and superior fire resistance.

- Compliance: Meets national fire safety standards, ensuring reliable protection in case of fire.

- Sound Insulation: Reduces noise transmission, enhancing privacy and comfort.

wooden fire door

wooden fire door

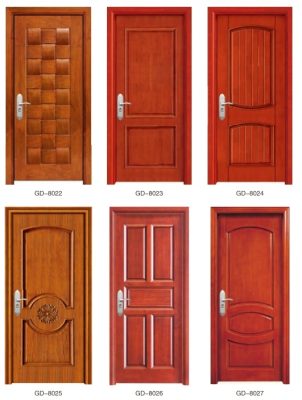

Wooden fire doors come in various types, each designed to meet specific fire safety requirements and aesthetic preferences. These doors are classified based on their fire resistance rating, construction materials, and functional features. Below are the main types of wooden fire doors commonly used in construction: 1. Solid Wood Fire Doors Solid wood fire doors are constructed using a single slab of fire-rated timber or engineered wood. These doors offer excellent fire resistance while maintaining a traditional, robust appearance. The solid construction ensures that the door remains durable and reliable even in high-traffic areas. Fire Rating: Typically available in 30-minute (FD30) or 60-minute (FD60) ratings. Applications: Ideal for residential properties, offices, and public buildings where both aesthetics and fire protection are important. 2. Solid Wood Composite Fire Doors These doors feature a solid core made from composite materials, such as particleboard or mineral core, which is then covered with a fire-resistant wood veneer or laminate. The composite core provides enhanced fire protection and thermal insulation while the outer layer mimics the appearance of natural wood. Fire Rating: Commonly rated for 60 to 90 minutes. Applications: Used in commercial and institutional settings that require higher fire resistance levels, such as hospitals, hotels, and schools. 3. Flush Fire Doors Flush wooden fire doors have a smooth, flat surface without decorative panels. These doors are often minimalist in design and provide a sleek, modern appearance. Despite their simple look, flush fire doors are engineered for high fire resistance and are commonly used in contemporary architecture. Fire Rating: Available in 30, 60, and 90-minute ratings. Applications: Perfect for modern office spaces, retail stores, and apartment complexes where a clean, streamlined look is desired. 4. Panel Fire Doors Panel fire doors are designed with decorative raised or recessed panels on their surface, offering both fire protection and a more traditional or ornate appearance. The paneling does not compromise the door’s fire-resistant properties, as these doors are constructed with fire-rated materials beneath the surface. Fire Rating: Typically 30 to 60 minutes. Applications: Suitable for residential buildings, heritage properties, or spaces where aesthetics are a priority alongside fire safety. 5. Glazed Fire Doors Wooden fire doors with glazed panels incorporate fire-resistant glass that allows natural light to pass through while still providing fire protection. These doors are equipped with intumescent seals around the glazing to prevent the spread of smoke and flames through the glass during a fire. Fire Rating: Usually 30 or 60 minutes, depending on the glass specification. Applications: Commonly used in corridors, offices, and entrance areas where visibility or light transmission is needed without compromising fire safety. 6. Acoustic Fire Doors Acoustic wooden fire doors are designed to offer both fire resistance and soundproofing capabilities. These doors are constructed with materials that help reduce noise transmission while also meeting fire protection standards. Fire Rating: Often 30 or 60 minutes, with acoustic ratings up to 45dB. Applications: Ideal for hotels, offices, and meeting rooms where sound insulation and fire safety are essential. 7. Double-Leaf Fire Doors Double-leaf wooden fire doors consist of two door leaves that can open together or independently. These doors are often used in wide doorways to allow larger openings for pedestrian flow or emergency evacuation. Fire Rating: Available in 30, 60, or 90-minute ratings. Applications: Frequently found in hospitals, shopping malls, and theaters where large numbers of people may need to evacuate quickly during a fire. Conclusion Wooden fire doors provide critical fire protection while offering flexibility in design. Whether it’s solid wood, composite, glazed, or acoustic, each type of wooden fire door serves specific needs in different building environments. With the right fire rating and proper installation, these doors can effectively slow the spread of fire and smoke, ensuring the safety of occupants.