Guangdun Door Industry has provided a detailed overview in this article, covering various aspects of fire doors, including:

- The different types of fire doors based on materials, ratings, and opening mechanisms.

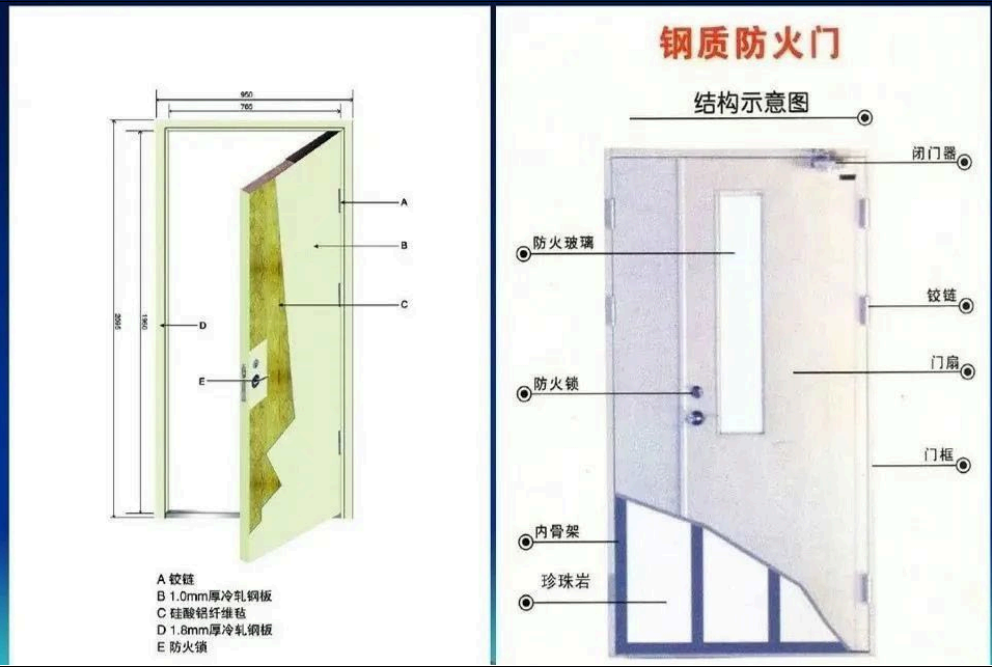

- A breakdown of fire door components, such as door frames, leaf structures, fire-resistant infill materials, and hardware like intumescent seals and closers.

- Insights into the market price range for fire doors, highlighting cost variations between wooden, steel-wood, and steel fire doors.

- The applications of different fire door ratings, explaining where Class A, B, and C fire doors are best suited within a building.

This comprehensive guide aims to assist construction companies in making informed decisions when procuring fire doors, helping them balance safety, functionality, and cost efficiency.

1. Overview of Fire Doors and Installation

1.1 Definition of Fire Doors

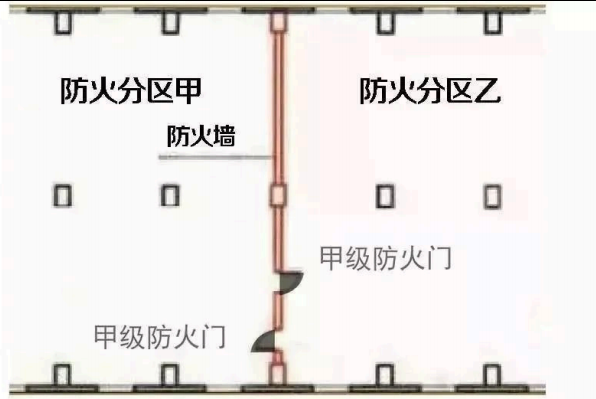

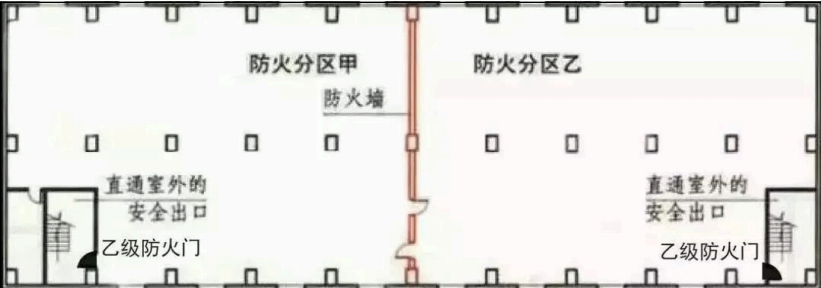

Fire doors are one of the essential fire protection measures in building construction, typically installed on firewalls, at stairwell entrances, or at openings of service shafts. Their primary function is to prevent the spread of smoke and flames during a fire, playing a crucial role in minimizing damage and ensuring the safety of occupants.

1.2 Areas of Application for Fire Doors

Fire doors are commonly installed in key areas requiring fire separation, including:

- Boiler rooms, transformer rooms, diesel generator rooms, and combustible material storage in basements.

- Kitchens in non-residential buildings, doors leading to outdoor staircases.

- Fire control rooms, equipment rooms for fixed fire suppression systems, fire pump rooms, and ventilation control rooms.

- Inspection doors on vertical service shafts.

- Enclosed stairwells, smoke-proof stairwells, their anterooms, fire elevator lobbies, doors leading to atriums or other passageways.

- High-rise residential buildings.

1.3 Types of Fire Doors

Fire doors can be categorized based on their fire resistance rating, material, opening mechanisms, and usage requirements:

- By Material:

- Wooden fire doors, steel fire doors, composite fire doors. Steel fire doors are the most commonly used due to their superior fire resistance.

- By Opening Mechanism:

- Normally closed fire doors: Remain closed with the help of door closers and activate automatically during a fire.

- Normally open fire doors: Typically kept open by electromagnetic door holders and automatically close in case of fire.

- By Specifications:

- Single-leaf, double-leaf, with or without glass panels, with or without transom windows, etc.

A standard fire door consists of several components: frame, leaf, fire-resistant infill material, fire-rated hinges, fire locks (panic bars), intumescent seals, door closers, coordinators, electromagnetic holders, and fire-resistant glass.

1.5 Fire Door Installation Guidelines

- Install Class A fire doors on firewalls and fire-resistance-rated structures.

2.Use Class B fire doors for evacuation stairwells and their anterooms.

3.Class C fire doors are suitable for vertical shafts.Fire Door Engineering and Cost.

- Important equipment rooms should have appropriately rated fire doors.

2. Key Factors in Fire Door Cost Control

2.1 Selection of Fire Door Materials

The cost of fire doors varies by material. The most common types, ranked by price, are:

- Wooden Fire Doors: Made from flame-retardant treated wood, these doors are the least expensive, typically ranging from ¥300 to ¥350 per square meter.

| first rate | b grade | c grade | |

| fire endurance | ≥1.2h | ≥0.9h | ≥0.6h |

| Door frame: (flame-retardant treatment) | 52×105mm | 52×100mm | 52X100mm |

| Door fan panel | A 2.5mm thick splint(Back closed primer) | A 2.5mm thick splint(Back closed primer) | A 2.5mm thick splint(Back closed primer) |

| Door fan thickness | 50mm | 50mm | 45mm |

| Internal skeleton four-sided handspike | Jasun / Hemlock / Eucalyptus sp | Jasun / Hemlock / Eucalyptus sp | Jasun / Hemlock / Eucalyptus sp |

| Inside the filling | Perlite + fireproof board | Perlite + fireproof board | Perlite + fireproof board |

| Smoke bar | The frame was used for 15mm | The frame was used for 15mm | The frame was used for 15mm |

| first rate | b grade | c grade |

2.Steel-Wood Fire Doors: Combining the strength of steel with the lightweight nature of wood, these doors cost between ¥300 and ¥400 per square meter.

3.Steel Fire Doors: With steel frames, panels, and fire-resistant infill, these doors offer excellent fire resistance at around ¥500 per square meter.

- Fire Door Engineering and Cost

2.2 Fire Door Rating and Cost Differences

Higher fire resistance ratings result in thicker, more durable materials, and thus, Class A fire doors are more expensive than Class B or Class C doors.

2.3 Fire Door Opening Mechanism Costs

As mentioned earlier, fire doors can be either normally open or normally closed. Normally open fire doors, equipped with electromagnetic door holders, closers, and coordinators, cost about ¥30 more per square meter than their normally closed counterparts.

2.4 Fire-Resistant Infill Materials

Common infill materials include:

- Organic Insulation Materials: Though effective, these materials, such as EPS or foam PVC, are falling out of favor due to their flammability and the release of toxic fumes when burned.

- Inorganic Fireproof Materials: These include rock wool, mineral wool, glass wool, etc. While they offer excellent fire resistance, some materials lack structural integrity or are more expensive.

- Magnesium-Oxide Fireproof Cores: These infills, made from magnesium oxide and expanded perlite, offer excellent fire insulation at lower costs and are now widely used in fire doors.

2.5 Surface Finishing Costs

Decorative fire doors, often featuring wood-grain transfer printing, are more expensive than standard fire doors. Consider project needs and budget when selecting surface treatments.

2.6 Control Fire Door Dimensions

Oversized fire doors, especially those exceeding 2100mm in width or 2300mm in height, can only be produced by qualified manufacturers. Custom sizes often come at a significantly higher price compared to standard dimensions.

3. Cost-Saving Strategies for Fire Door Projects

3.1 Optimize Fire Door Rating Selection

| scheme | Engineering Quantities (m2) | Fire door grade of pipe well | Comprehensive unit price (RMB / m2) | Covalent (YUAN) |

| Plan one | 945 | Class C steel fire proof door | 420 | 396900 |

| Plan 2 | 945 | Class B steel fire proof door | 460 | 434700 |

| amount of money | 37800 |

In a high-rise residential project, using Class C fire doors instead of Class B for vertical shafts resulted in a cost saving of approximately ¥37,800 without compromising on safety.

3.2 Choose the Right Opening Mechanism

Opting for normally closed fire doors instead of normally open ones in less-trafficked areas can reduce costs by approximately ¥145,500.

| scheme | Engineering Quantities (m2) | Often open doors / often closed doors | Comprehensive unit price (RMB / m2) | Covalent (YUAN) |

| Plan one | 4850 | normal close | 450 | 2182500 |

| Plan 2 | 4850 | normally open | 480 | 2328000 |

| amount of money | 145500 |

4. Key Points to Consider for Fire Door Projects

4.1 Design Phase Considerations

- Choose fire door materials wisely.

- Select appropriate fire ratings.

- Prioritize cost-effective fire-resistant infill materials.

- Be mindful of surface finishing.

- Control door dimensions.

- Select the correct opening mechanism for each area.

4.2 Tendering Phase Considerations

- Utilize bulk purchasing to reduce material costs.Fire Door Engineering and Cost.

- Clarify responsibility boundaries between contractors for door installation and related works.Fire Door Engineering and Cost.

4.3 Construction Phase Considerations

- Ensure correct payment schedules based on work completion stages.

- Monitor material specifications and ensure adherence to quality standards.

4.4 Settlement Phase Considerations

- Accurately define project scope to avoid double-charging.

- Maintain detailed completion drawings and settlement records for transparent invoicing.

This article provides a comprehensive look into fire door engineering, installation, and cost management, focusing on how strategic choices in material, rating, and mechanism can optimize both safety and expenses. If you’re looking to procure high-quality fire doors for your construction projects, our factory offers a range of certified, fire-resistant doors designed to meet the stringent standards of modern buildings.