Characteristics and Applications of Fire Doors

Fire doors are crucial components in the overall fire safety strategy of any building. These specially designed doors are engineered to prevent the spread of fire, smoke, and heat from one area to another, ensuring that occupants have sufficient time to evacuate safely. In this article, we explore the key characteristics and applications of fire doors, particularly focusing on fire rated doors and fire resistance doors, and how GD Door Industry, a leading fire door supplier, plays a pivotal role in providing high-quality solutions for various industries.Characteristics and Applications of Fire Doors

Key Characteristics of Fire Doors

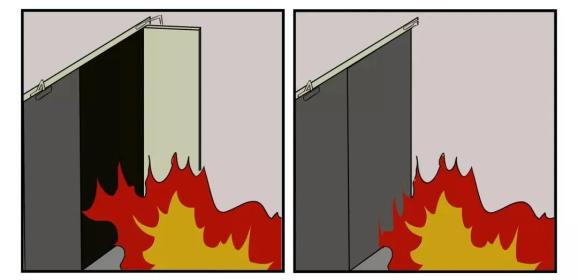

- Fire Resistance The primary characteristic of any fire resistance door is its ability to withstand fire for a specified period. Fire doors are classified according to their fire resistance duration, which typically ranges from 30 minutes to 120 minutes. This fire-resistance rating is crucial in ensuring the door can withstand high temperatures and prevent the spread of fire to other areas of the building.

- Durable Materials A fire rated door is constructed from materials that can resist both heat and fire. Common materials include steel, wood, and composites that have been treated or designed to delay the passage of fire. These materials contribute to the door’s ability to maintain structural integrity under fire conditions.

- Insulation Properties In addition to fire resistance, fire doors are also designed to have high thermal insulation properties. This feature helps to limit the heat transfer through the door, thus preventing the surrounding environment from reaching dangerous temperatures. The insulation prevents the spread of heat and smoke, further enhancing safety.

- Smoke Sealing An effective fire door supplier ensures that their products are equipped with smoke seals. These seals expand when exposed to heat, preventing smoke from passing through the gaps around the door. Since smoke inhalation is one of the leading causes of death in fires, smoke control is an essential feature of any fire-rated door.

- Self-Closing Mechanism Most fire rated doors are equipped with self-closing devices that ensure the door automatically closes after being opened. This is critical in maintaining the fire barrier in case of a fire outbreak. These devices are designed to close the door quickly without requiring manual intervention, ensuring it remains securely shut during a fire.

- Testing and Certification All fire resistance doors must undergo rigorous testing to meet specific safety standards. These tests simulate real fire conditions to determine how long a door can withstand heat, smoke, and flame. Certifications such as the EN 1634 (for Europe) or UL 10B (for North America) are key indicators of quality and performance.

Applications of Fire Doors

- Fire Protection in Commercial Buildings Fire rated doors are widely used in commercial buildings to compartmentalize fire zones and contain fires to their source. Offices, shopping malls, hotels, and hospitals all rely on fire doors to protect both people and property. By dividing these buildings into fire-resistant zones, fire resistance doors prevent fire from spreading rapidly, allowing occupants time to evacuate safely and emergency services to intervene.

- Industrial Applications Ifire doors plFire rated door suppliers l

- Residential Buildings and High-Rise Apartments Hifire rated door supplier such

- Healthcare Facilities In hospfire resistance doors are critifire rated doors that me

- Schools and Educational Institutions Edfire resistance doors ar

- Public Transport and Airports Airportsfire doors tofire resistance doors t

- Warehouses and Storage Facilities Warehouses storingFire rated doors are essenfire door supplier, GD D

- Data Centers Dafire rated doors thaFire resistance doors in

Technological Expertise in Fire Door Manufacturing

The manufacturing of fire doors is a highly specialized field that requires advanced technological knowledge and precise engineering. A fire rated door supplier like GD Door Industry combines years of expertise with cutting-edge technology to produce fire doors that meet stringent safety standards. The process involves the careful selection of materials, the application of advanced fire-resistant coatings, and the integration of specialized hardware to ensure the door performs optimally under fire conditions.

One of the key aspects of fire door manufacturing is the fire resistance testing process. Each door undergoes rigorous testing to ensure that it can withstand high temperatures and fire exposure for the duration specified by the relevant standards, such as EN 1634-1 or UL 10B. These tests simulate real-world fire scenarios, including flame exposure, smoke leakage, and heat transfer, to evaluate the door’s effectiveness in preventing fire and smoke spread.

Furthermore, modern fire door technology also incorporates the latest advancements in thermal insulation and smoke control. By using innovative materials such as intumescent seals, which expand when exposed to heat, manufacturers can enhance the door’s ability to contain fire and smoke within a designated area. The precise integration of these components requires both technical know-how and advanced production techniques.

At GD Door Industry, engineers and technicians work meticulously to develop fire rated doors that provide long-lasting protection. By employing automated production lines, sophisticated quality control systems, and a commitment to research and development, the company ensures that every door meets the highest safety standards. This technical proficiency and commitment to innovation make GD Door Industry a leader in the global fire door supplier market, trusted by architects, builders, and safety experts worldwide.

I really enjoyed this article—it was insightful and well-written! The website’s

layout is clean and user-friendly.

Статья расширила мой кругозор, огромное спасибо за труд!