1. Loss

In fire resistance testing, “integrity” refers to a fire door’s ability to prevent flames or hot gases from passing through. Various national and international standards assess this crucial aspect

- Chinese Standard – GB/T 7633, British Standard – BS 476-22, aEuropean Standard – EN 1634-1:

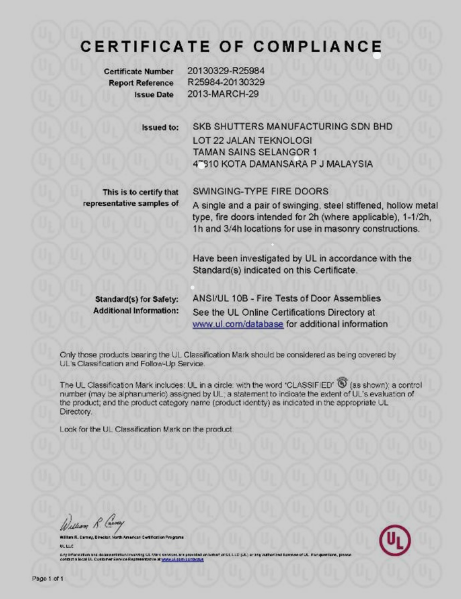

- American Standard – NFPA 252, **ANSI/ULANSI/UL 10B/C: The door must remain latched with no perforations after both fire resistance and hose stream tests. An ignition cotton pad catching fire or flames appearing on the unexposed side are also considered failures.

For any fire door manufacturer or fire door factory, ensuring compliance with these standards is vital to meet safety regulations and market demands globally.

2. Loss of Insulation

Fire insulation refers to a fire door’s ability to reduce heat transmission, preventing high temperatures from spreading to the protected side of the door. Here’s how different standards measure it:

- GB/T 7633 (China) and BS 476-22 (UK): Failure occurs if the average temperature on the non-fire-exposed side rises more than 140°C above the initial temperature or if the maximum point exceeds 180°C. In some cases, failure is indicated when the door frame or tracks reach 360°C above the initial temperature.

- EN 1634-1 (Europe): Follows similar criteria as GB/T 7633, with thresholds set at 140°C and 180°C for average and maximum temperature increases, respectively.

- NFPA 252 and ANSI/UL 10B/C (USA): U.S. standards are generally more lenient regarding insulation, focusing mainly on the first 30 minutes of heat rise.

Maintaining high insulation performance is essential for any fire door manufacturer aiming to supply doors that meet international specifications.Analysis of Fire Door Fire Resistance.

3. Fire Door Opening Direction.Analysis of Fire Door Fire Resistance.

The direction in which a fire door opens plays a role in its testing and certification. In China, fire doors are typically tested with the door opening outward, away from the furnace. However, international standards vary depending on door type:

- Symmetrical steel doors: Generally tested to open outward.

- Symmetrical wooden doors: Tested to open inward.

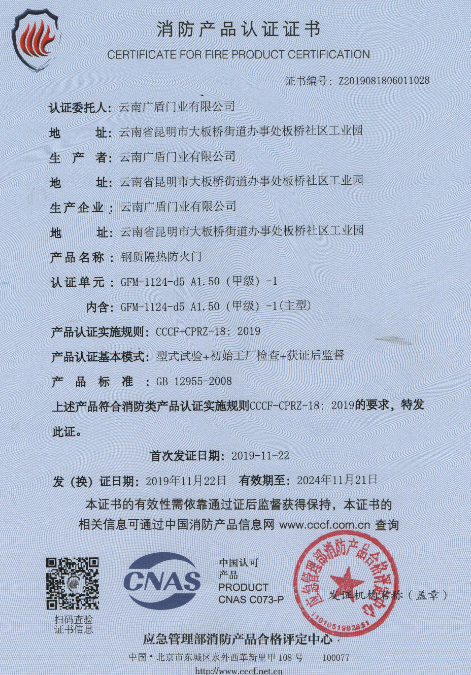

Understanding these nuances is crucial for global manufacturers like us at Yunnan Guangdun Door Industry Co., Ltd., who supply fire doors to multiple markets, ensuring compliance with different regulations.

4. Symmetrical vs. Asymmetrical Doors

Asymmetrical fire doors must undergo testing on both sides, according to international standards like EN 1634-1. Additionally, hardware installed on the surface, such as panic push bars, needs to be tested from both sides. This makes it important for a fire door factory to account for such specific requirements during production to ensure that the door’s structural integrity is maintained from all angles.

5. Fire Door Sizes

Fire door sizes vary considerably between countries:

- Common sizes in the U.S. are 3×7, 4×8, 6×7, and 8×8 feet.

- In China, dimensions tend to be more diverse, requiring greater flexibility from manufacturers.

At Yunnan Guangdun Door Industry Co., Ltd., we offer a variety of door sizes and customizations to meet both international and domestic specifications, whether you’re looking for standard-sized or bespoke fire doors.

6. Door Thickness and Ratings

The thickness of a fire door directly impacts its fire resistance duration:

- British and European standards:

- For 0.5-hour fire resistance, the door is generally 44mm thick.

- For 1.0-hour resistance, 54mm.

- For 1.5-hour resistance, 58mm.

- For 2.0-hour resistance, 64mm.

Manufacturers need to ensure that fire doors meet these thickness guidelines for compliance with fire ratings and certifications.

7. Water Impact and Deformation

In some tests, fire doors are also subjected to water impact, which assesses their resilience after exposure to fire and rapid cooling with water. Failure can occur if the door is penetrated by water or if deformation exceeds 1.5 times the door’s thickness after the water impact.

At Yunnan Guangdun Door Industry Co., Ltd., we ensure that our fire doors not only meet fire resistance standards but also withstand deformation and water impact, providing comprehensive safety solutions.