10 Things You Should Know About Fire Doors

- 1、The Science Behind Fireproofing Wooden Doors

- 2、Key Factors Affecting Fireproofing Quality

- 3、Why Fireproof Wooden Doors?

- 4、Safe Operating Procedures for Using Fire Doors

- 5、Understanding Fire Doors and Their Functions

- 6、Installation Locations for Fire Doors

- 7、Routine Inspection and Maintenance of Fire Doors

- 8、Fire Door Evacuation Tips

- 9、Alternatives to Fire Doors

- 10、The Fire Door Manufacturing Process

When it comes to building safety and fire prevention, fire doors play an essential role in safeguarding lives and property. As a leading manufacturer in the industry, Yunnan Guangdun Door Industry Co., Ltd. specializes in producing high-quality fire doors that comply with stringent safety standards and provide reliable protection in case of a fire. Whether you are an architect, contractor, or property owner, understanding the critical aspects of fire doors can help you make informed decisions to enhance safety in your buildings.

In this article, we will explore 10 important things you should know about fire doors, covering key topics such as the different types of fire doors, their construction materials, installation requirements, and maintenance tips. With a focus on delivering comprehensive information, we aim to provide valuable insights for anyone interested in improving fire safety measures.

By choosing Yunnan Guangdun Door Industry Co., Ltd., you are opting for a trusted partner with expertise in manufacturing certified fire-rated doors that meet international standards. Our products are designed to offer superior protection, combining durability and aesthetic appeal with the highest safety performance. Read on to discover the essential facts about fire doors and how they can make a significant difference in your building’s fire safety strategy.

How Fire Doors Work: Understanding the Fire Resistance of Wooden Fire Doors

When people hear the term “wooden fire door,” it often raises eyebrows—how can a door made of wood be fire-resistant? The answer lies in the sophisticated fireproofing processes applied to the timber used in these doors. Wooden fire doors are engineered to resist fire and prevent its spread, ensuring safety in case of an emergency. This section explores how these doors achieve fire resistance and the methods used in their production.

1、The Science Behind Fireproofing Wooden Doors

Wood, by nature, is a flammable material, so how do wooden fire doors provide effective fire protection? The secret lies in treating the wood with specialized fire retardants. Common methods for fireproofing wood include:

- Spraying Method: Fire retardants are sprayed onto the surface of the wood. This method is typically used for wood surfaces that will not undergo further processing, such as thin panels less than 10mm thick. However, it is not suitable for producing wooden fire doors as it only provides surface-level protection.

- Soaking Method: Involves immersing wood in a fire retardant solution. Similar to the spraying method, this is primarily used for thin wood panels and is not ideal for full-sized fire doors.

- Steaming Method: The most widely used method for fireproofing wood in fire door manufacturing. This process involves placing the wood in a steaming chamber where it absorbs the fire retardant solution, providing deep penetration and enhanced fire resistance.

- Vacuum and Vacuum Pressure Methods: These are the most effective techniques, involving placing wood in a vacuum to remove air and then introducing fire retardant under pressure. However, due to the high cost of equipment, these methods are not commonly used in many regions, including most fire door manufacturers in China.

2、Key Factors Affecting Fireproofing Quality

For wooden fire doors to be effective, it is crucial that the fireproofing process is performed correctly. The quality of fire resistance depends on several factors, including the wood’s moisture content and the concentration of fire retardant absorbed:

- Moisture Content of the Wood: The drier the wood, the more effectively it absorbs fire retardant solutions. Wood with a moisture content below 15% can absorb more fire retardant than wood with higher moisture levels. This results in higher fire resistance, as indicated by a higher oxygen index (a measure of the wood’s ability to resist ignition).

- Order of Adding Fire Retardant: It is essential to add the fire retardant to the solution before placing the wood in the chamber. This ensures that the wood absorbs the correct concentration from the beginning, improving the overall fireproofing quality.

- Concentration of the Fire Retardant: Using a pre-mixed fire retardant solution at the recommended concentration allows for better absorption and a more uniform distribution within the wood, enhancing its fire resistance.

3、Why Fireproof Wooden Doors?

Wooden fire doors, treated with the appropriate fire retardants, provide several benefits:

- Aesthetic Appeal: They retain the natural look and feel of wood, making them ideal for buildings where visual appeal is essential, such as hotels, offices, and residential buildings.

- Fire Protection: Properly treated wooden fire doors can effectively block the spread of fire and smoke, allowing occupants more time to evacuate safely.

- Regulatory Compliance: Compliant wooden fire doors meet national and international fire safety standards, ensuring that buildings are both safe and legally compliant.

4、Safe Operating Procedures for Using Fire Doors

With the continuous development of urban construction and the improvement of people’s living standards, fire safety awareness is gradually increasing. Fire doors, as a crucial part of fire safety facilities, play a vital role in preventing the spread of fire and protecting lives. Proper usage of fire doors is essential for controlling fire outbreaks and ensuring the safety of occupants. Understanding and adhering to safe operating procedures not only enhances self-rescue capabilities but also reduces the risk of fire incidents.

5、Understanding Fire Doors and Their Functions

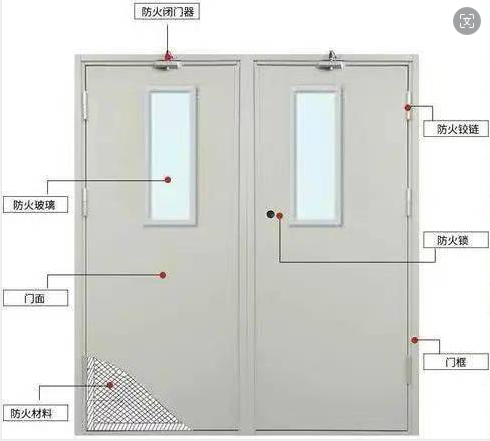

Fire doors are a type of specialized door designed to prevent the spread of fire by compartmentalizing different areas of a building. They are widely used in public spaces such as shopping malls, hospitals, schools, and other commercial and residential buildings. Fire doors serve multiple functions, including fire resistance, smoke control, toxin prevention, sound insulation, and providing a safe evacuation route during emergencies. As an essential component of fire safety systems, they ensure the safe evacuation of people while helping to contain and extinguish fires.

6、Installation Locations for Fire Doors

The installation of fire doors should comply with building design requirements and fire safety codes. Typically, fire doors are installed in areas with high foot traffic, such as passageway entrances, evacuation routes, kitchens, and other locations prone to fire hazards. It is crucial to keep the area around the fire doors clear of any obstructions to ensure unimpeded access and functionality. Proper placement and maintenance of fire doors are vital for the safety of both property and personnel.

7、Routine Inspection and Maintenance of Fire Doors

- Regular Inspections: It is recommended to conduct a comprehensive inspection of fire doors every three months. Key aspects to check include door integrity, frame condition, lock functionality, and the state of fire-resistant seals. Any irregularities should be promptly reported to maintenance professionals for immediate resolution.

- Cleanliness and Care: The surface of the fire door should be kept clean and free of labels or posters. Avoid using sharp objects that might scratch the door, as this can compromise its durability and effectiveness.

- Keep Doors Unobstructed: Fire doors should remain closed under normal circumstances. If a fire door needs to be held open for an extended period, use an appropriate hold-open device to secure it.

- Seal Integrity: The sealing materials on fire doors are critical to their performance. Do not damage or replace these materials without proper authorization. If the seals show signs of aging or damage, notify maintenance personnel for replacement immediately.

8、Fire Door Evacuation Tips

- Learn Proper Door Operation: Fire doors typically operate using a push or pull mechanism. In case of a fire, first check for smoke in the room. If there is no smoke, try pushing the door open. If the door feels heavy or stuck, switch to pulling the handle. If smoke is present, crouch near the door, cover your mouth and nose with a wet cloth, and push the door with your back to avoid inhaling toxic fumes.

- Follow Safe Exit Routes: When entering a public corridor, remain calm and avoid causing a stampede. Move quickly along the designated escape route and avoid backtracking, overcrowding, or blocking the passageway.

- Evacuate Quickly: In the event of a fire, evacuate the danger area as quickly as possible using safe routes. In crowded situations, stay calm and avoid yelling. Follow the guidance of safety personnel and evacuate in an orderly manner.

9、Alternatives to Fire Doors

While fire doors offer unique fire-resistant properties, alternatives can be used temporarily if fire doors are not available. For example, using wet towels or cloths to seal door and window gaps can help prevent the spread of fire and toxic smoke into a room. These temporary measures can be life-saving in emergency situations.

10、The Fire Door Manufacturing Process

The production of fire doors involves a meticulous and highly regulated process designed to ensure that each door meets stringent safety and fire resistance standards. Understanding the fire door manufacturing process can provide valuable insight into the craftsmanship and quality control involved in producing these critical safety components. Below, we outline the key steps involved in the production of fire doors:

1. Material Cutting and Flame Retardant Treatment

The first step in manufacturing a fire door is selecting and cutting the raw materials to the required specifications. For wooden fire doors, the material is subjected to a flame retardant impregnation treatment. This process involves soaking the wood in a flame retardant solution to enhance its fire resistance. The amount of solid flame retardant used varies depending on the fire rating required: for Class A fire doors, the wood must absorb more than 110 kg of flame retardant per cubic meter, while Class B fire doors require over 90 kg per cubic meter. This treatment significantly improves the wood’s ability to withstand high temperatures and prevent the spread of flames.

2. Drying the Material

After the flame retardant treatment, the wood must be thoroughly dried. Proper drying is essential to prevent warping and ensure the structural integrity of the door during assembly. The drying process also helps to lock in the flame retardant chemicals, making the wood more resistant to combustion.

3. Frame Construction

Next, the dried and treated wood is processed into specific dimensions to create the door frame or skeleton. This step, known as frame fabrication, involves precise cutting and shaping of the material to form the internal framework of the fire door. The frame provides structural support and forms the basis for attaching other components.

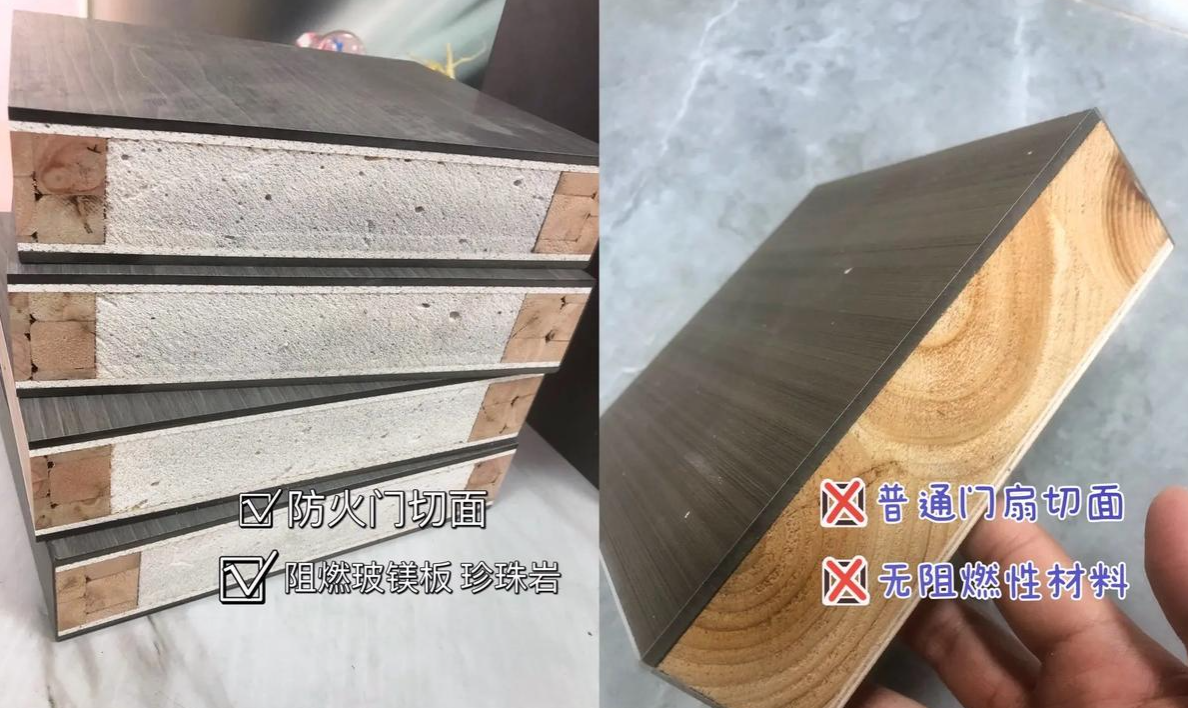

4. Inserting Fire-Resistant Core Materials

Once the frame is ready, it is filled with fire-resistant core materials. These materials, which may include gypsum, vermiculite, or specialized fire-resistant board, are crucial for the door’s ability to withstand high temperatures and prevent fire penetration. The treated wood is subjected to a second drying process to ensure all components are moisture-free and stable.

5. Surface Panel Fabrication

The next step involves preparing the surface panels, which are attached to both sides of the door frame. The panels are precision-machined, sanded, grooved, and fitted with mortises and tenons to ensure a perfect fit. Intumescent fire seals are then embedded into the door. These seals expand when exposed to heat, sealing gaps around the door to prevent the spread of smoke and flames. The door is then assembled, ensuring that all parts are securely fastened and aligned.

6. Priming and Finishing

After assembly, the door undergoes a thorough inspection for quality control. Any defects are corrected before the door receives a base coat of primer. This coating not only protects the door but also prepares it for the final paint or veneer finish, depending on the desired aesthetic. After the primer has dried, the fire door is inspected again to ensure it meets all quality standards.

7. Final Inspection, Packaging, and Storage

The final stage in the fire door manufacturing process involves a comprehensive inspection of the completed door. This includes checking for structural integrity, correct fitting of components, and adherence to design specifications. Once the door has passed all inspections, it is carefully packaged to protect it during transportation and storage. The packaged doors are then moved to a storage area, ready for distribution and installation.

The manufacturing of fire doors is a complex process that requires attention to detail and strict adherence to safety standards. Each step, from material treatment to final inspection, is designed to ensure that the finished product provides reliable protection in the event of a fire. By choosing fire doors from a reputable manufacturer like Yunnan Guangdun Door Industry Co., Ltd., you can be confident that you are investing in a product that meets the highest standards of fire safety and durability.