Stainless Steel Fire Resistance Rating Report

Introduction-Stainless Steel Fire Resistance Rating

The inherent oxidation resistance and high-temperature strength of stainless steels make them ideal for use in buildings and structures where fire resistance is critical. Among the various families of stainless steels, austenitic stainless steels are particularly advantageous due to their superior performance under elevated temperatures. However, because fires are typically short-term events, ferritic and duplex stainless steels also offer viable options for fire resistance applications.

It is important to note that stainless steels, as raw materials, lack an intrinsic fire resistance rating. Instead, fire resistance is assessed through rigorous testing of specific fabrications under standardized conditions, such as those outlined in BS 476, particularly parts 20, 21 (load-bearing elements), and 22 (non-load-bearing elements).

The absence of software from the Steel Construction Institute (SCI) for calculating the behavior of loaded stainless steel sections in a fire presents a challenge. Nevertheless, Chapter 8 of the latest Design Manual for Structural Stainless Steel offers valuable guidance on fire resistance design principles, catering to structural engineers working with stainless steel fire-rated doors and components.

Fire Testing and Standards

Fire resistance testing is a cornerstone for determining the performance of materials like stainless steel. According to BS 476 standards, many test methods—such as combustibility, fire propagation, and surface spread of flames—are not directly relevant to stainless steels. These metals are inherently non-combustible and resist flame spread due to their stable surface and resistance to oxidation at high temperatures.

For manufacturers like GD Fire Door Supplier, stainless steel’s properties are particularly advantageous in fabricating fire-rated doors, fire resistance doors, and other critical building components. Such doors not only meet rigorous testing requirements but also provide long-lasting solutions for fire safety.Stainless Steel Fire Resistance Rating.

Galvanized Steel and Fire Resistance

When enhancing the fire resistance of stainless steel components, the use of materials like galvanized steel can further optimize performance. Galvanized steel plates, including zinc-coated steel plates and hot-dip galvanized steel plates, are frequently employed due to their corrosion-resistant properties. These materials complement stainless steel, offering additional protection against environmental factors while maintaining fire resistance.

GD Fire Door Supplier integrates corrosion-resistant steel plates into its fire-resistant doors, ensuring enhanced durability and compliance with strict fire safety standards. This combination of materials delivers reliable solutions for both load-bearing and non-load-bearing applications in modern construction.

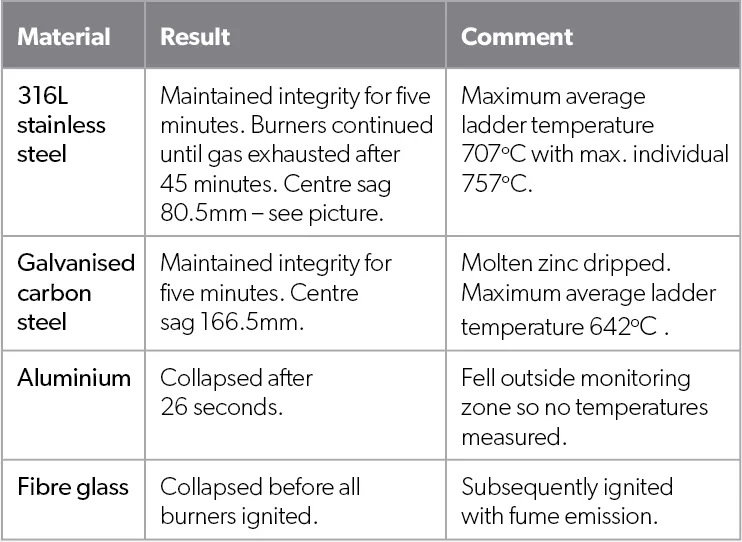

Results of Fire Testing on Stainless Steel Components

Fire testing highlights the robust performance of stainless steel components under extreme conditions, underscoring their suitability for critical applications like fire-rated doors and fire resistance doors.

In tests conducted for Stewart Fraser Ltd., their fire-resistant doors and frames, constructed using 316-grade stainless steel and insulated with a non-combustible board filling, demonstrated exceptional fire containment. After 60 minutes, the temperature on the “safe” side of the door reached only 98°C, well below the critical threshold. The test was concluded after 2 hours and 10 minutes, with the doors and frames fully intact. Notably, the fire was entirely contained on the “attack” side for over two hours, with only minor thermal distortion and discoloration on the “safe” side.

Another test, performed on a 1.4362 (2304) duplex stainless steel bulkhead supplied by Avesta AB in 1991, further validates the fire resistance of stainless steels. The bulkhead featured a 1.5 mm corrugated profile skin and a ceramic wool insulating filler, designed for maritime applications. During testing, the “attack” temperature reached a staggering 1100°C within 15 minutes, radiating a bright orange glow. Despite some distortion and insulation smoke, the “safe” side maintained a temperature below 30°C for 40 minutes and only rose to 110°C after 60 minutes. After 120 minutes, the bulkhead continued to meet the criteria for resistance to smoke and hot gases as defined by the International Maritime Organization Resolution A517 (XIII).

These results underscore the importance of consulting experienced manufacturers like GD Fire Door Supplier early in the design process. This proactive approach ensures compliance with fire safety standards while avoiding costly redesigns. For example, using hot-dip galvanized steel plates or zinc-coated steel plates as structural reinforcements in fire resistance doors can enhance both durability and thermal performance.

By integrating advanced materials such as corrosion-resistant steel plates, GD Fire Door Supplier delivers reliable fire safety solutions tailored to meet the demands of various industries, from maritime to commercial construction.

Heat Resisting Properties of Stainless Steels

Stainless steel’s exceptional heat resistance is a critical factor in its application for fire-rated doors and fire resistance doors. Grades like 304 (1.4301) and 316 (1.4401) exhibit oxidation resistance at temperatures exceeding 800°C and remain structurally stable without melting until reaching over 1375°C. This robustness ensures superior performance even in intense, short-term fire scenarios where transient conditions dominate.

Mechanical and Physical Properties Under Fire Conditions

The mechanical and physical properties of stainless steel under fire conditions demonstrate its resilience compared to other materials:

- Mechanical Strength: At 700°C, the 304 and 316 austenitic grades retain about 55% of their ambient temperature strength. Their 0.2% proof strength decreases from 225–308 MPa at ambient temperatures to 95–131 MPa at 700°C.

- Elastic Modulus: The elastic modulus drops from around 200 KN/mm² at ambient temperatures to 144 KN/mm² at 700°C for type 304 stainless steel, significantly outperforming carbon steels, which can retain as little as 9% of their modulus at 800°C.

These properties highlight why GD Fire Door Supplier prioritizes high-grade stainless steel in its products, ensuring both structural integrity and safety during fire exposure.

Thermal Expansion and Distortion Management

The higher thermal expansion rates of austenitic stainless steels can lead to distortion, particularly under transient fire conditions with significant thermal gradients. While lower thermal conductivity in the austenitic family can help contain heat flow, it can also exacerbate distortion. Proactively addressing these challenges is essential in fire-rated door design.

By integrating materials such as zinc-coated steel plates, hot-dip galvanized steel plates, or corrosion-resistant steel plates into the framework, GD Fire Door Supplier mitigates distortion while enhancing structural resilience. These innovative solutions ensure that fire resistance doors remain operational and effective during emergencies.

Careful allowances for potential distortion, particularly for components like hinges and frames, enable the production of fire-rated doors that deliver reliable performance even under extreme conditions. Such comprehensive design considerations underscore GD’s commitment to delivering industry-leading fire safety solutions.

Conclusion

Stainless steel’s exceptional fire resistance and mechanical properties make it an indispensable material in modern fire safety applications, particularly in the design of fire-rated doors and other protective structures. As the demand for robust fire protection solutions grows in both the Chinese and global markets, meeting stringent fire inspection standards has become a critical factor for the success of real estate and infrastructure projects.

At GD Fire Door Supplier, we take pride in manufacturing fire resistance doors that meet China’s most comprehensive certifications. Our fire doors are not only fully compliant with rigorous fire inspection requirements but are also offered at the most competitive prices in the market. Whether for domestic or international projects, our high-quality products ensure safety, compliance, and cost-effectiveness for our clients worldwide.

Trust GD to deliver reliable, certified, and affordable fire door solutions tailored to your project’s needs. Contact us today to learn how we can help you safeguard your investments with industry-leading fire protection materials.