Research on the Loss of Fire Integrity in Steel Fire Doors: Analysis and Improvement Measures

Zhang Yulin, Tang Jie, Cui Zhixiang, Qin Hao, Zi Yong, Li Weifeng

Kunming University of Science and Technology (Postcode: 273400)

Yunnan Provincial Product Quality Supervision and Inspection Institute (Postcode: 250102)

Abstract:

This paper analyzes the causes behind the loss of fire integrity in steel fire doors during fire resistance tests. The deformation mechanism of door panels under fire exposure is also discussed, and improvement measures to enhance the fire integrity of steel fire doors are proposed. Experimental results demonstrate that the suggested improvements significantly enhance the fire integrity performance of steel fire doors.

Keywords: Steel fire doors, fire integrity, deformation mechanism, fire resistance performance, fire door manufacturer

Introduction to Steel Fire Doors and Their Role in Fire Protection

Steel fire doors are essential components of fire protection systems, designed to provide a critical barrier to the spread of fire and smoke within buildings. These fire-resistant doors are engineered to maintain their integrity and insulating properties under high heat, offering both fire resistance and smoke containment.

As per GB12955-2008 “Fire Doors” standards, the primary fire performance criteria for fire doors are fire integrity and thermal insulation. In real-world fire tests, it is often observed that steel fire doors fail to maintain their fire integrity, with significant numbers of failures being reported. This issue highlights the urgent need to enhance the fire resistance of steel fire doors, as they play a pivotal role in preventing the rapid spread of fire in critical infrastructures such as high-rise buildings, hospitals, hotels, stations, and theaters.

Fire integrity is a crucial measure of a fire door’s ability to stay intact during a fire, preventing the passage of fire and smoke. The loss of fire integrity in steel fire doors compromises their role in fire protection, making it imperative for manufacturers and engineers to address these challenges.

Analysis of Fire Integrity Loss in Steel Fire Doors

1.1 Forms of Fire Integrity Loss in Steel Fire Doors

Steel fire doors are primarily constructed from steel plates, and steel is a highly conductive material with a significant thermal expansion coefficient. When subjected to heat on one side, the steel door’s frame tends not to deform significantly. However, the thermal differential between the two sides of the door leads to bending and twisting of the door panel. Without proper structural support, excessive deformation can result in misalignment between the door frame and panel, causing the door seal to fail. This failure allows flames and smoke to breach the door, leading to a complete loss of fire integrity.

For single-leaf doors, the hinge side is typically fixed to the door frame, preventing significant misalignment. On the other side, the door is usually connected to the frame by a fire-rated lock, while the top and bottom edges are not directly connected to the frame. As a result, the panel tends to bow inward, especially near the locking mechanism, causing the top and bottom edges to curl outward. This phenomenon leads to frame-panel misalignment and eventual loss of fire integrity.

For double-leaf doors (including paired doors), the door panels are typically equipped with stops, which prevent significant misalignment. However, at the joint between the two doors, the fixed leaf is constrained only at the top and bottom edges, leaving the center section more prone to inward bowing. The active door leaf is connected to the fixed door leaf via a fire-rated lock, but the sides remain unconnected to the frame. As the deformation of the door panel increases, the gap between the two doors widens. When this gap exceeds the door’s seal overlap, the seal fails, allowing hot gases to escape and further enlarging the gap. Once the gap reaches a certain size, the door loses its fire integrity.

1.2 Deformation Mechanism of Steel Fire Door Panels During Fire Tests

The door panel of a steel fire door typically consists of a steel plate and a core material. When exposed to fire, the steel plate expands due to heat, while the core material, which typically has a lower thermal expansion coefficient, remains less deformed. This difference in thermal expansion between the steel plate and the core material causes the door panel to warp, especially around the edges.

The deformation is most prominent at the door’s edges, where the structural connection between the steel plates and the core material creates a constrained area. During fire testing, the difference in thermal expansion causes the steel structure to bend, and this thermal stress increases with the intensity of the heat exposure. The greater the stiffness of the steel structure and core material, the more pronounced the deformation.

At the edges, the steel frame is typically made up of several connected layers, which can further exacerbate the bending. When the temperature differential between the layers is high, the resulting thermal stress can lead to further warping and misalignment of the frame and door leaf.

The connection points, where the steel plates meet, experience a more drastic temperature change, leading to significant thermal gradients. The differences in temperature cause expansion on the heated side and contraction on the cooler side, generating thermal stress that can increase the likelihood of the door losing its fire integrity. This thermal stress is further amplified if the door’s frame is poorly connected or lacks adequate insulation.

Proposed Improvements to Enhance the Fire Integrity of Steel Fire Doors

To enhance the fire integrity of steel fire doors, manufacturers should focus on improving the structural design to minimize deformation during fire exposure. Key areas for improvement include:

- Use of advanced materials for the door core, such as fire-resistant insulation that can expand under heat to fill gaps, thus maintaining the seal integrity.

- Reinforced frame connections that reduce the risk of frame-panel misalignment.

- Optimized sealing systems, including intumescent seals, that expand when exposed to heat and provide better sealing around the door edges.

- Improved hinge and lock systems that allow for slight movement of the door panels without compromising the overall fire protection performance.

By addressing these issues, steel fire doors can better withstand the stresses of fire exposure and maintain their fire integrity for a longer duration, effectively blocking the spread of fire and smoke.

2. Improvement Measures

Based on the analysis in the previous section, the main strategies to reduce door panel deformation should focus on two key areas: (1) minimizing the deformation of edge steel structures and reducing their bending rigidity, thereby interrupting the heat transfer route at the door panel edges; and (2) implementing measures to improve the bending stiffness and flexural strength of the core material to enhance its ability to suppress the deformation of the steel structure.

2.1 Reducing Deformation of Edge Steel Structures and Lowering Their Bending Rigidity

- Optimizing Edge Frame Construction

If the door frame uses panels with direct bent edges, it is advisable to bend the panel on the non-fire side. This adjustment helps reduce the temperature of the fire-exposed side and minimizes the amount of free deformation due to heat. The width of the bent edge on the fire-exposed side should be kept as small as possible. Adhesive bonding should be used to connect the panels to the frame, with additional welding points to prevent adhesive layer peeling. The spacing between welding points should be as large as possible to reduce the critical compressive stress at the panel edge and minimize the thermal stresses that lead to deformation. - Using Independent Frames with Enhanced Thermal Resistance

When both the fire-exposed side and the non-fire side are bent separately, and then connected by welding or adhesive bonding, the connection should prioritize adhesive bonding, with supplementary welds to prevent peeling. The welding points should be spaced out to allow for localized instability when the adhesive fails, which reduces thermal stress and deformation. The edge of the fire-exposed panel should extend over the non-fire side’s panel to reduce lateral constraints and further lower critical stress levels. - Independent Frame Design for Enhanced Thermal Stability

It is highly recommended to use independent frames, especially at the lock edges and top and bottom areas of the door. The thickness of these independent frames should be appropriately increased to improve their thermal mass, thus reducing heat exposure on the frame and minimizing free deformation due to thermal expansion. The frame should ideally incorporate thermal insulation, with the insulation positioned closer to the fire-exposed side. This design improves the temperature difference across the insulation boundary, lowering the cold side’s temperature and reducing thermal deformation. Adhesive bonding should be used for the frame connection, with spot welding as an auxiliary method to decrease critical stress levels.

2.2 Increasing Bending Stiffness and Flexural Strength of the Core Material to Suppress Deformation

A highly effective approach to enhance the door’s performance is to install a steel frame around the core material, especially along the edges where locks are mounted and at the top and bottom. The steel frame should have an appropriate thickness to improve its flexural rigidity and its ability to resist bending deformation at the door’s edges. Additionally, thermal insulation should be applied to both the fire-exposed side and the edges of the steel frame to minimize the temperature difference, thus reducing the thermal bending deformation.

The connection between the core steel frame and the door’s edge structure should be secure to ensure efficient force transmission. There are several ways to connect the steel frame to the core material:

- Inlaid Method: Commonly used for thicker frame structures, where the steel frame is embedded into the core material, effectively transmitting bending loads.

- Mechanical Fastening: Suitable for various structural types, this method effectively transmits bending loads, although it may be more complicated to implement and is not ideal for mass production.

- Welding: For the fire-exposed side panel, welding is used to connect it to the steel frame at a point near the steel frame’s bending neutral axis. This reduces the thermal stress acting on the steel frame and minimizes bending deformation.

By welding the fire-exposed side panel to the steel frame, the distance between the welded points can be increased to further reduce compressive stress at the panel’s edge. This helps minimize thermal stress and reduces the overall bending deformation of the door panel.

2.3 Additional Measures

Steel fire doors are integral structures, and improving their fire-resistance integrity involves not only addressing door panel deformation but also considering the coordination of other structural components. Therefore, attention should also be paid to the following aspects:

- Reducing Door Frame Cross-Section

Reducing the door frame’s cross-sectional size can increase its deformation and help align it more closely with the door panel’s deformation, reducing the differential movement between the two components. - Using High-Density Inorganic Core Materials

The core material of the door should have a higher density, especially for the fire-resistive core. This helps to dampen the deformation of the door panel and improve its overall resistance to bending. - Ensuring Proper Sealing at the Door Gap

The gap between the door panels should meet the required standards, and a fire-resistant seal should be placed along the door gap. This ensures that the door maintains its integrity under high temperatures, preventing gaps where hot gases could leak through. - Minimizing Step Structures on the Door’s Edge

The edges of the door should not have excessive steps. Ensuring a smooth, continuous edge helps prevent potential weak points in the structure that could lead to failure under fire conditions.

By implementing these improvement measures, we can significantly enhance the fire-resistance integrity of steel fire doors, increasing their ability to maintain their function during a fire emergency. This will help prevent the loss of integrity, which is crucial in ensuring the safety of both the building and its occupants.

Analysis of Steel Fire Door Performance and CAD Integration in Fire Protection Systems

5. Calculation Results and Stress Analysis

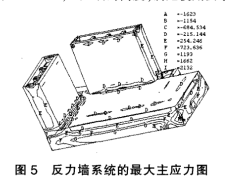

Figure 5 presents the maximum principal stress distribution in the reaction wall system under horizontal load applied to the north wall. The analysis reveals that most of the reaction wall and the top slab of the foundation are in a state of compression. Under the anticipated maximum horizontal service load, the stress concentration at the wall’s uppermost edge becomes a critical point for ensuring structural stability.

For steel fire doors, understanding the stress response of structural systems under fire load is crucial. The insights gained from this study could inform the optimization of fire door designs, particularly for applications in critical infrastructures such as high-rise buildings, industrial facilities, and emergency exits. By improving the integrity of door systems under heat and pressure, manufacturers can enhance compliance with global fire safety standards like GB 12955-2008.

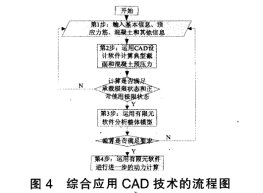

6. Conclusion and CAD Applications for Fire Door Manufacturing

The research highlights the effectiveness of CAD software in designing and optimizing complex systems, such as reaction walls and foundation systems, which are integral to fire safety testing environments. Using CAD technology for steel fire doors enables manufacturers to:

- Evaluate Fire Resistance Under Simulated Conditions

CAD software can simulate the load-bearing capacity and fire resistance integrity of steel fire doors. By modeling dynamic fire conditions, such as extreme heat and pressure, manufacturers can predict how their doors will perform in real-world emergencies. This ensures adherence to standards like GB/T 9978.1-2008. - Integrate Finite Element Analysis (FEA)

The integration of FEA tools allows for a comprehensive analysis of the entire fire door structure, from the steel frame to the core insulation. For instance, understanding how stress concentrates around door edges and sealing gaps can guide design improvements, minimizing deformation during fires. - Enhance Batch Production

Optimizing the design process with CAD tools also ensures that improvements are practical for mass production. While meeting the demands of fire door manufacturers, such as reducing material costs and simplifying production, it also ensures higher product consistency and compliance across batches.

Practical Measures to Improve Steel Fire Door Performance

The study underscores that improving the fire resistance integrity of steel fire doors is a systematic engineering task. Solutions include:

- Optimizing Sealing Systems: The installation of fire-resistant seals in door gaps must account for dynamic deformation during fire exposure. Seals should be capable of maintaining their function even when door frames and panels expand or distort due to heat.

- Strengthening Door Frames: Door frame designs should minimize cross-sectional size while maintaining sufficient rigidity to synchronize deformation with door panels. This reduces misalignment and enhances the fire door’s sealing effectiveness.

- Double-Leaf Door Enhancements: Adding cover plates at the seams of double-leaf fire doors can significantly improve overlap, preventing gaps caused by thermal deformation.

Forward-Looking Recommendations for Fire Door Design

To enhance global competitiveness, Chinese fire door manufacturers can leverage these findings to innovate in product design and fire safety compliance. By adopting advanced CAD techniques and conducting rigorous testing, manufacturers can ensure their steel fire doors meet the most stringent requirements for fire resistance.

Moreover, focusing on long-tail keywords like “steel fire door manufacturer,” “fire door stress analysis,” and “high-performance fire doors” will boost online visibility and help position companies as leaders in the fire safety materials market.

These integrated improvements ensure that steel fire doors are not only highly reliable in emergencies but also cost-effective and suitable for large-scale production. By continuously refining their manufacturing processes, manufacturers can better serve growing markets worldwide, from residential buildings to industrial complexes.

References

- GB 12955-2008, Fire Doors Standard.

- GB/T 9978.1-2008, Fire Resistance Test Methods for Building Components: General Requirements.

- Fengxue Liu. Discussion on Steel Fire Door Structure and Fire Resistance.

- Zhao Liu, Jie Chen. Thermal Response Simulation of Steel Structures in Fires, Chongqing University Journal, 2009.