The Difference Between Explosion-Proof Doors and Blast-Resistant Doors

Understanding the distinction between explosion-proof doors and blast-resistant doors is crucial for selecting the appropriate safety solutions for different applications. Although the terms are sometimes used interchangeably, there are specific differences in their design, functionality, and performance. Below are the key distinctions:

Technical Standard for Explosion-Proof Doors by Yunnan Guangdun Door Industry Co., Ltd.

Introduction

This standard is proposed and governed by the Technical Department of Yunnan Guangdun Door Industry Co., Ltd. The main drafter of this standard is Zhang Yulin. The primary purpose of this document is to outline the design, construction, and application of explosion-proof doors to ensure safety in high-risk environments.

Explosion-Proof Door Specifications

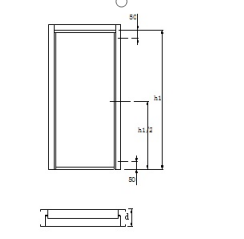

Scheme 1:

- Pressure Resistance: 0.19 MPa (190 KPa)

- Door Panel Material: 5.0 mm thick steel plate

- Door Frame: 50 mm x 120 mm x 5.0 mm groove steel

- Hinge: Pressure-bearing hinge

- Lock Options: Explosion-proof hand wheel lock or escape push bar lock

- Additional Features: Frequently open doors should be equipped with a door-closing device.

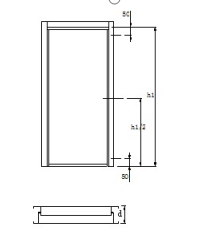

Scheme 2:

- Pressure Resistance: 0.15 MPa (150 KPa)

- Door Panel Material: 4.0 mm thick steel plate

- Door Frame: 50 mm x 120 mm x 4.0 mm square pipe

- Hinge: Pressure-bearing hinge

- Lock Options: Explosion-proof hand wheel lock or escape push bar lock

- Additional Features: Frequently open doors should be equipped with a door-closing device.

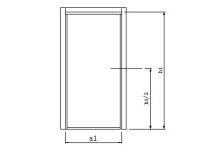

Scheme 3:

- Pressure Resistance: 0.11 MPa (110 KPa)

- Door Panel Material: 3.0 mm thick steel plate

- Door Frame: 50 mm x 120 mm x 3.0 mm square pipe

- Hinge: Pressure-bearing hinge

- Lock Options: Explosion-proof hand wheel lock or escape push bar lock

- Additional Features: Frequently open doors should be equipped with a door-closing device.

Introduction of the advantages and performance

1. In the case of explosion, the explosion incident pressure and reflection force are set according to the forecast. The explosion-proof door can withstand the blasting pressure within the range and achieve the necessary protection effect to prevent casualties and property losses.

2. After the explosion occurs, the pre-set explosive force is not reached, and the explosion-proof door can still be used normally.

3. When the explosion occurs, the explosive force is pre-set, which can deform, but the components of the door can still be used to avoid personnel being trapped and trapped.

4, the necessary closed isolation function, to prevent the direct convection of the isolated space and the outside air, in order to reduce the separated, protected space by the outside pollution.

5, Explosion-proof door is a kind of safety facility, with self-closure function and emergency escape function.

6, explosion-proof door shock wave resistance is common: 0.021Mpa=21Kpa,0.045Mpa=45Kpa,0.069Mpa=69Kpa.

Anti-Explosion Door Enterprise Standard

Preface

This standard is proposed by Yunnan Guangdun Door Industry Co., Ltd., and is managed by its Technology Department. The main drafting unit for this standard is the Technical Department of Yunnan Guangdun Door Industry Co., Ltd. This document represents the first issuance of the standard for steel anti-explosion doors.

1. Scope

This standard specifies the levels, technical requirements, test methods, inspection rules, marking, packaging, transportation, and storage of steel anti-explosion doors. It serves as the technical basis for the design, manufacturing, and acceptance of these doors. The standard is mainly applicable to steel anti-explosion doors used in special public and civil buildings.

2. Normative Reference Documents

The following documents are essential for the application of this standard. For dated references, only the specified edition applies. For undated references, the latest edition (including all amendments) applies.

- GB 5824: Building Doors and Windows Hole Size Series

- GB 17565: General Technical Conditions for Anti-Theft Security Doors

- JB/T 3054: Single Flat Open Multi-Function Door

- GB 3836: National Standard for Explosion-Proof Products

3. Terms and Definitions

This standard adopts the following terms and definitions:

3.1 Steel Anti-Explosion Door

A metal door designed to resist the gas shock waves produced by explosives under specified conditions.

3.2 Anti-Explosion Level

The classification of the anti-explosion level of a door based on its ability to withstand shock waves from explosive gases under specified test conditions.

4. Product Types, Anti-Explosion Grades, and Marking

4.1 Explosive Use and Explosive Distance

This section should include a table specifying the use of explosives and the corresponding safe distances for each type of anti-explosion door. (You can insert a detailed table here as needed.)

Additional Information (Optional Sections)

You may also consider including sections on the following topics for a more comprehensive standard:

- 5. Technical Requirements: Detailed specifications regarding the construction materials, dimensions, and performance criteria for each grade of steel anti-explosion doors.

- 6. Test Methods: Procedures for testing the doors’ resistance to explosive shock waves, including equipment used and evaluation criteria.

- 7. Inspection Rules: Guidelines for inspecting and certifying the compliance of anti-explosion doors with the standard.

- 8. Marking and Labeling: Information on the proper labeling of doors, including grade, manufacturer details, and safety warnings.

- 9. Packaging, Transportation, and Storage: Instructions on the correct handling, packaging, and storage of anti-explosion doors to maintain their integrity and performance.

| rank | Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | Ⅵ | Ⅶ |

| Explosion distance / m | 2.0 | 2.0 | 2.5 | 2.0 | 2.5 | 2.0 | 2.0 |

| Examite weight / kg | 5.0 | 4.0 | 5.0 | 2.0 | 3.0 | 1.0 | 0.5 |

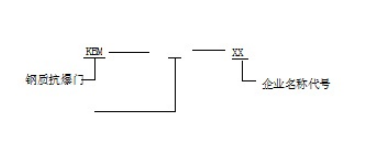

4.2 Product Marking

Example 1: KBM- -QSBY

This marking indicates a steel anti-explosion door produced by Yunnan Guangdun North Door Industry Co., Ltd.

5. Technical Requirements

5.1 Materials and Accessories

5.1.1 Door Frame and Door Panel Material

- Door Frame: Made of 120 mm wide national standard groove steel.

- Door Panel Skeleton: Constructed using 50 mm x 70 mm x 3.0 mm thick square pipe.

- Door Panel: Welded inside and outside with 3.0 mm thick high-quality carbon steel plates.

- Insulation: The door panel is filled with insulation material to ensure thermal resistance and sound insulation.

5.1.2 Hardware Accessories

All hardware accessories installed on the steel anti-explosion door must comply with the corresponding standards and be compatible with the door’s functional requirements.

5.2 Appearance Quality

5.2.1 Welding Requirements

- Welding on the steel anti-explosion door must be firm, with evenly distributed solder joints.

- There should be no false welding or burn-through.

- External surfaces must be polished and flat, free of welding joints, welding slag, scratches, and other impurities.

5.2.2 Spraying Requirements

- The door must undergo oil removal, rust removal, and phosphorization before spraying.

- After spraying, the coating must be uniform, smooth, and free from defects such as accumulation, rough spots, bubbles, and areas of incomplete coverage.

5.2.3 Surface Quality

The surface of the door frame and door panel must be free from obvious defects, such as dents, scratches, or other surface imperfections.

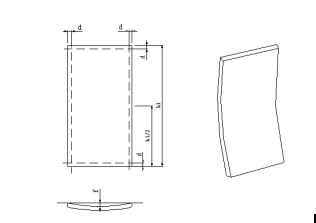

5.3 Dimension and Shape Tolerance

5.3.1 Dimension Tolerance

The dimensional tolerance for the steel anti-explosion door frame and other external measurements are provided in Table 1.

| toponym | Limit deviation | toponym | Limit deviation |

| Door fan height | 0-3 | Gate frame slot height | +10 |

| Door fan width | 0-2 | Door frame thickness | +1-1 |

| Door fan thickness | +1-1 | Door frame slot width | +1-1 |

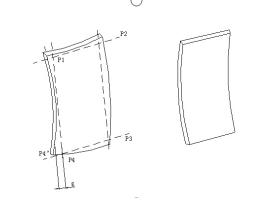

5.3.2 Position Tolerance

The position tolerance of the steel anti-explosion door is detailed in Table 2.

| name | Measurement items | common difference |

| door case | Two-diagonal length difference between the grooves | ≤5 |

| door leaf | Two-diagonal length differences | ≤3 |

| torsion resistance | ≤4 | |

| Height directional degree | ≤1 | |

| Door frame, door fan | The height difference between door frame and door fan combination (front surface) | ≤1 |

5.3.3 Coordination Size

5.3.3.1 Lock Hole

When there is a lock hole on the steel door frame, the maximum mating gap between the lock tongue and the lock hole should not exceed 3 mm.

5.3.3.2 Activity Gap

The activity gap between the door leaf (door fan) and the door frame should not exceed 10 mm.

5.3.3.3 Door Gap

The gap between the door leaf and the door frame should not exceed 10 mm. The opening edge of the door should not be greater than 5 mm in the closed state.

Steel Blast-Resistant Doors Standard

Introduction

Blast-Resistant doors are special-purpose doors designed to withstand internal or external explosions. These doors are now widely used in various industries, including petrochemicals, power electronics, and high-speed rail, particularly in shelters, substations, control rooms, passages, and hazardous materials warehouses. Boiler rooms and flammable or explosive warehouses have also begun adopting Blast-Resistant doors.

Currently, there is no unified national or industry standard in China for the production of Blast-Resistant doors. The application range and industry demand for Blast-Resistant doors are expanding, and the required specifications are increasingly diverse. The previous enterprise standards of our company could no longer meet these new requirements. Therefore, in January 2014, we revised this standard to suit new demands.

This standard applies to Blast-Resistant doors designed to resist blast pressures between 50 and 500 kPa.

Major Differences Between This Standard and Q/IIDW 23-2006

- Classification and Basic Parameters: Updated the categories and basic parameters (see sections 4 of both the 2006 and current versions).

- Symbols and Codes: Adjusted the symbols and codes (see sections 5 of both versions).

- General Requirements: Removed general requirements outlined in the 2006 version’s section 6.

- Explosion Resistance: Revised explosion resistance standards (see section 6.1.2.1 in the 2006 version and section 6.1.1 in the current version).

- Fire Integrity: Modified fire integrity standards (see section 6.1.2.2 in the 2006 version and section 6.1.2 in the current version).

- Sealing Performance: Updated sealing performance requirements (see section 6.1.2.4 in the 2006 version and section 6.1.4 in the current version).

- Commercial Content: Removed business-related content from sections 6.1.3 and 6.1.4 of the 2006 version.

- Shape and Position Tolerances: Updated shape and position tolerances (see section 6.5.4 in both versions).

- Assembly Tolerances: Revised assembly tolerances (see section 6.6 in both versions).

- Document Formatting and Technical Content: The standard has been reorganized and formatted as per GB/T 1.1-2000 guidelines.

This standard was proposed and revised by Yunnan Guangdun door Co., Ltd.

1. Scope

This standard specifies the terms, classifications, basic parameters, symbols, codes, requirements, test methods, inspection rules, marking, packaging, transportation, and storage of steel Blast-Resistant doors. It is applicable to industrial buildings with steel Blast-Resistant doors designed to withstand shock wave pressures up to 500 kPa.

2. Normative References

The following documents are referenced within this standard. For dated references, only the dated version is applicable. For undated references, the latest version, including any amendments, is applicable:

- GB/T 191: Packaging Storage and Transport Pictorial Marking

- GB/T 6388: Transport Packaging Receiving and Dispatching Markings

- GB/T 7633: Test Methods for Fire Resistance of Doors and Shutters

- GB 8624: Classification of the Burning Behavior of Building Materials and Products

- GB 9969.1: General Principles for Preparation of Instructions for Use of Industrial Products

- GB/T 13686: Classification and Test Methods for Air and Rainwater Permeability of Building External Doors

- GB/T 14436: General Rules for Preparation of Industrial Product Guarantee Documents

3. Terminology

The following terms are applicable to this standard:

3.1 Steel Blast-Resistant Door

A door constructed with steel frame, door leaf, and skeleton, filled with thermal insulation material, and equipped with special Blast-Resistant hinges, three-way linkage bolts, and anti-blast mullions. It is designed to withstand blast impact and meets fire integrity requirements.

4. Classification and Basic Parameters

4.1 Classification

Steel Blast-Resistant doors are swing doors classified by door leaf type into single-leaf, double-leaf, and asymmetrical double-leaf. For pressure levels above 300 kPa, only single-leaf doors are used.

4.2 Basic Parameters

4.2.1 Explosion Resistance Levels

The pressure resistance levels for steel Blast-Resistant doors are: 50 kPa, 100 kPa, 200 kPa, 300 kPa, and 500 kPa. Non-standard levels can be provided for special cases.

4.2.2 Fire Integrity

The fire integrity of steel Blast-Resistant doors is greater than 3.0 hours.

4.2.3 Door Dimensions and Configuration

This includes door width, height, opening direction, and the position of the main door in the case of asymmetrical double-leaf doors.

5. Symbols and Codes

The code format for steel Blast-Resistant doors is as follows:

- KBM – □ □ – □ □

Where:

- KBM: Steel Blast-Resistant Door

- Explosion Environment: (Indoor Explosion: “L”, Outdoor Explosion: no symbol)

- Blast Pressure (kPa): Specified level

- Opening Size: Width and height in decimeters (dm)

Example:

- KBM-1922-20: Represents a steel Blast-Resistant door designed to withstand a blast pressure of 50 kPa, with an opening width of 20 dm (2000mm) and a height of 22 dm (2200mm), suitable for outdoor explosion sources.

6. Requirements

6.1 Performance Requirements

Steel Blast-Resistant doors must withstand the designated explosion force and remain functional after the blast. The frame should not deform plastically, and the impact surface of the door leaf may have minor dents as agreed upon between supplier and user.

6.1.1 Explosion Resistance Levels

The peak pressure resistance levels are categorized into nine levels: 50 kPa, 100 kPa, 200 kPa, 300 kPa, and 500 kPa.

6.1.2 Fire Integrity

In case of an explosion-induced fire, the fire integrity of the steel Blast-Resistant door should be greater than 3.0 hours to prevent fire spread.

6.1.3 Penetration Resistance

To withstand flying debris during an explosion, the impact surface panel of the steel Blast-Resistant door must have sufficient penetration resistance.

6.1.4 Sealing Performance

The door should maintain a seal to prevent the ingress of toxic gases generated during an explosion. Sealing Performance Requirement: When the pressure difference between the interior and exterior is 10 Pa, the air permeability per meter of gap should be ≤ 6.0 m³/m.h (GB/T 13686 Class V).

6.1.5 Automatic Closing

As the timing of an explosion is unpredictable, steel Blast-Resistant doors used as personnel entry/exit points must have an automatic closing function.

6.1.6 Emergency Escape

The doors must be equipped with an emergency escape device to facilitate evacuation during an explosion. For doors facing internal explosions, the opening direction should be opposite to the escape direction of personnel.

6.1.7 Sound and Light Alarm

To maintain a normally closed state, the doors must have a sound and light alarm system that activates when the door is opened, reminding personnel to close the door immediately.

6.1.8 Remote Monitoring

As part of a security system, steel Blast-Resistant doors should have a sound and light alarm system and provide a remote monitoring signal interface for security personnel to monitor the door’s status remotely.

6.2 Materials and Accessories

6.2.1 Materials

- Door Frame and Leaf: Carbon structural steel and high-quality galvanized steel sheet.

- Filling Material: Fire-resistant insulation material.

6.2.2 Accessories

- Door Closer: The closing force should match the weight of the door leaf.

- Sub-Door Leaf Locking: A detachable fixed pressure plate.

- Blast-Resistant Hinges: Custom-designed Blast-Resistant hinges for either swing or pivot.

- Special Locks: Handles and push-rod lock assemblies with automatic closing and escape functions.

- Rubber Seals: Fitted between the door frame and leaf for sealing.

- Smoke Seals: Installed around the door leaf to prevent smoke infiltration.

6.3 Appearance Requirements

6.3.1 Welding

Welding should follow the design requirements, with no false welding, burn-through, or internal cracks. Plug welding areas must be ground smooth.

6.3.2 Coating

The surface should be coated with anti-corrosion primer, with an even, smooth, and defect-free finish.

Technical Standard for Steel Explosion-Proof Doors

1. Scope

This standard specifies the terms, classifications, basic parameters, symbols, requirements, testing methods, inspection rules, marking, packaging, transportation, and storage for steel explosion-proof doors. It is applicable to industrial buildings where the peak pressure of impact waves is below 500 kPa for all pressure levels of steel explosion-proof doors.

2. Normative References

The following documents are incorporated into this standard. For dated references, only the edition cited applies. For undated references, the latest edition (including amendments) applies.

- GB/T 191: Packaging – Pictorial Markings for Handling of Goods

- GB/T 6388: Transport Packaging – Receiving and Dispatch Marks

- GB/T 7633: Fire Resistance Test Method for Doors and Shutters

- GB 8624: Classification for Burning Behavior of Building Materials and Products

- GB 9969.1: General Principles for Preparation of Instructions for Use of Industrial Products

- GB/T 13686: Classification and Test Method for Air Permeability and Rain Penetration of External Doors in Buildings

- GB/T 14436: General Principles for the Preparation of Quality Documents for Industrial Products

3. Terms and Definitions

The following terms apply to this standard.

3.1 Steel Explosion-Proof Door:

A door made of steel materials, including door frame, door leaf, and skeleton structure, with a filling of insulating materials. It is equipped with special explosion-proof hinges, three-way linkage bolts, and explosion-proof mullions, capable of resisting blast impact and maintaining fire integrity.

4. Classification and Basic Parameters

4.1 Classification:

Steel explosion-proof doors are classified into single leaf, double leaf, and double-leaf (mother and child) types based on the door leaf structure. For impact wave pressure levels exceeding 300 kPa, single-leaf doors are recommended.

4.2 Basic Parameters:

- Blast Resistance Pressure Levels: 50 kPa, 100 kPa, 200 kPa, 300 kPa, and 500 kPa. Non-standard values are acceptable for special cases.

- Fire Integrity: Greater than 3.0 hours.

5. Symbols and Codes

KBM——□ □——□ □

- Explosion Scenario: (Indoor explosion: “L”, Outdoor explosion: No symbol)

- Blast Impact Pressure (kPa)

- Opening Specifications (width, height, unit: dm)

- Product Code: Denotes Steel Explosion-Proof Door

Example:

KBM-1922-20 indicates a steel explosion-proof door designed for an outdoor explosion source, with an impact pressure of 50 kPa and an opening width of 20 dm (2000 mm) and height of 22 dm (2200 mm).

6. Requirements

6.1 Performance Requirements:

The steel explosion-proof door should be able to withstand the predetermined explosion force. Post-explosion, the door should still be operational without significant plastic deformation. Slight dents on the pressurized side are acceptable.

6.1.1 Blast Resistance:

Divided into nine levels: 50 kPa, 100 kPa, 200 kPa, 300 kPa, 500 kPa.

6.1.2 Fire Integrity:

Fire resistance should be greater than 3.0 hours to prevent fire spread after an explosion.

6.1.3 Penetration Resistance:

The door’s front panel should resist penetration from flying debris caused by explosions.

6.1.4 Sealing Performance:

Should effectively seal to prevent the ingress of hazardous gases under explosion conditions.

6.1.5 Auto-Close Functionality:

Equipped with an automatic closing mechanism to ensure doors remain closed unless manually opened.

6.1.6 Emergency Egress:

Emergency egress devices should be installed to facilitate escape during an explosion event.

6.1.7 Alarm System:

An audible and visual alarm system should alert personnel when the door is opened, prompting immediate closure.

6.1.8 Remote Monitoring:

The door should have provisions for integration with remote monitoring systems, enabling real-time status tracking.

7. Testing Methods

- 7.1 Blast Resistance Test: Simulate explosion conditions in a qualified laboratory to assess deformation and structural integrity.

- 7.2 Fire Resistance Test: Conduct according to GB/T 7633 standards.

- 7.3 Sealing Test: Ensure conformity with GB/T 13686 requirements.

- 7.4 Functional Tests: Verify automatic closing, egress functionality, alarm system, and remote monitoring capabilities through repeated operation tests.

8. Inspection Rules

8.1 Factory Inspection:

Each door must pass inspection for appearance, dimensional accuracy, and functional performance before leaving the factory.

8.2 Type Inspection:

Includes all requirements specified in Section 6 and is necessary in cases of design changes, significant process modifications, or quality incidents.

9. Marking, Packaging, and Storage

9.1 Marking:

Each door must be permanently marked with the product name, model, specifications, manufacturer, date of production, fire rating, peak pressure, and standard number.

9.2 Packaging:

Products must be securely packaged in accordance with GB/T 191 to prevent damage during handling, transportation, and storage.

9.3 Storage:

Store in a dry, ventilated environment with protection against sunlight, moisture, and corrosion.

Design Concepts

- Purpose: The explosion-proof door is designed to withstand accidental or predictable explosions in industrial, chemical, and military settings. It aims to protect personnel and internal equipment from blast shock wave damage.

- Performance: The explosion-proof door system has superior resistance, capable of withstanding pressures up to 0.19 MPa (190 KPa). The system has been tested and certified by several internationally recognized organizations, ensuring reliable anti-explosion performance.

- Applications: Commonly used in industrial buildings such as petrochemical plants, power facilities, and military installations. It is also suitable for rooms requiring high safety standards, such as shelters, substations, control rooms, and corridors.

Performance Characteristics

- Weight and Handling: Explosion-proof doors are designed to be lightweight, making them easy to operate while meeting the project’s load requirements.

- Safety Features: The doors are equipped with safety mechanisms to function normally in non-explosive conditions.

- Compliance: Explosion-proof doors comply with the standards set by the Safety and Police Electronic Product Quality Testing Center of the Ministry of Public Security.

Classification of Explosion-Proof Doors

Explosion-proof doors are typically classified into two grades:

- Class A: Utilizes a 4.0 mm thick door frame and door panel with an 80 mm door. Suitable for high-risk areas such as ammunition depots and fire libraries.

- Class B: Uses a 3.0 mm thick door frame and door panel with a 55 mm door. Commonly used in general industrial applications.

- Explosion-Proof Doors:

- Purpose: Explosion-proof doors are designed to withstand a predetermined range of explosion incident pressures and reflective forces. Their primary function is to protect personnel and property by preventing or minimizing damage during an explosion.

- Performance Post-Explosion: If the explosion force does not exceed the specified threshold, the door can continue to function normally. In the event of an explosion that meets or exceeds the preset limits, the door may deform but will still maintain structural integrity, ensuring that occupants are not trapped or obstructed.

- Sealing and Isolation: These doors provide essential airtight and isolation capabilities, preventing direct airflow between the protected area and the external environment. This helps reduce contamination or pollution of the isolated space from external sources.

- Self-Closing and Emergency Escape: Explosion-proof doors are equipped with self-closing mechanisms and emergency escape features, allowing for quick evacuation in case of an emergency.

- Material and Design: Constructed using special industrial steel plates with precise mechanical data, they are fitted with high-performance hardware, ensuring both functionality and aesthetics. The doors are designed to resist explosions occurring outside industrial buildings, safeguarding personnel and internal equipment from blast waves and preventing the propagation of explosion hazards.

- 防爆门:

- Primary Function: Similar to explosion-proof doors, blast-resistant doors are intended to withstand high-pressure explosions. However, they are typically used in settings where direct exposure to blast forces is anticipated, such as military installations, chemical plants, and petrochemical facilities.

- Threshold and Resilience: While both door types can handle preset explosion forces, blast-resistant doors are often designed for higher thresholds and more extreme conditions. Their structural integrity remains intact, even under severe blast loads, to maintain security and safety.

- Durability After Explosion: These doors may deform under high-pressure loads but are engineered to remain operable or provide a controlled failure mode that does not compromise safety. They prevent debris from entering protected areas and ensure the continuity of operations post-blast.

- Applications: Blast-resistant doors are commonly used in environments with a high risk of deliberate or accidental explosions, where maintaining the operability of the door post-blast is critical.

Conclusion

Blast-Resistant Doors and Explosion-Proof Doors may seem similar, but they differ in terms of purpose, design, and performance.

1. Blast-Resistant Doors

- Purpose: Primarily used to prevent the damage caused by explosion shock waves (such as pressure waves generated by an explosion) to buildings or individuals inside. They are widely used in oil, gas, chemical plants, and military facilities where there is a risk of explosions.

- Design Features:

- Capable of withstanding and resisting high-pressure shock waves.

- Constructed from strong materials such as steel and composites.

- Designed to consider the reflection, absorption, and dispersion of explosion shock waves.

- May include specialized locking and hinge systems to ensure the door remains closed during an explosion.

2. Explosion-Proof Doors

- Purpose: Primarily used to prevent internal explosions (such as the explosion of flammable gases or chemicals in a confined space) from spreading outward. They are commonly used in industrial environments, such as hazardous material storage, laboratories, and factories where explosive gases or dust may be present.

- Design Features:

- Prevent the spread of flames, sparks, and high temperatures from an explosion to the outside environment.

- Focus more on isolation and sealing functions rather than directly resisting explosion shock waves.

- Often designed for airtightness to prevent flammable gas leakage.

- The structure is relatively simple and relies more on sealing and fire-resistant materials.

3. Summary of Differences

- Blast-Resistant Doors: Primarily defend against external explosion shock waves, typically used to protect individuals and building structures.

- Explosion-Proof Doors: Primarily used for internal explosion isolation and sealing, preventing flames and explosive gases from spreading outward.

In practical applications, the choice between the two types of doors depends on specific safety requirements and environmental conditions.

While both explosion-proof and blast-resistant doors are designed to provide protection against explosive forces, their usage, design specifications, and post-event functionality differ. Explosion-proof doors are generally employed in industrial settings to protect against accidental explosions and maintain normal operations even after a blast. In contrast, blast-resistant doors are used in high-risk environments where maximum resistance to explosive forces and security is paramount.

In essence, explosion-proof doors are ideal for industrial buildings to protect against accidental explosions, ensuring both the safety of personnel and the integrity of the structure. Meanwhile, blast-resistant doors are suited for applications requiring robust resistance and continued operability under extreme conditions, such as defense or high-risk industrial sites.

For industries looking to implement the highest standards of safety, selecting the appropriate door type based on the specific threat level and operational needs is essential. Guangdun Door Industry offers a wide range of both explosion-proof and blast-resistant doors, tailored to meet diverse safety requirements.